When you choose ladle shroud from a China factory, there are both risks and opportunities. Some suppliers may not always provide good quality or reliable service. It’s important to carefully check each supplier before you make your decision. Following a step-by-step plan can help you avoid costly mistakes. Pay close attention to key factors such as thermal shock resistance, corrosion resistance, and mechanical strength. These qualities ensure your ladle shroud performs well in demanding steelmaking environments.

Key Takeaways

- Make sure ladle shrouds can handle heat, corrosion, and force. This helps them last longer.

- Use materials like alumina-graphite or magnesia-carbon. Pick the one that fits your steel and casting needs.

- Find suppliers with the right certificates and lots of experience. Choose ones people trust to avoid problems.

- Ask for samples before you buy a lot. Check them well so you do not get bad quality later.

- Look at both price and quality. Buying better ladle shrouds saves money because you fix and replace them less.

Choose Ladle Shroud Criteria

When you pick ladle shroud from a China factory, you need to look at some important technical things. Each property helps keep the ladle shroud safe, strong, and working well during steelmaking.

Thermal Shock Resistance

Thermal shock resistance is very important when you choose ladle shroud. This property lets the shroud handle fast temperature changes without breaking. In steelmaking, ladle shrouds get hot quickly from molten steel. If the shroud cannot take this, it might break fast and stop work.

Tip: Pick ladle shrouds with a thermal shock resistance of 5 or more. This number is trusted in the industry and means the shroud is safe, even if you do not preheat it.

A high thermal shock resistance lets you use the shroud for cold starts and after long breaks. Makers do this by mixing the right powders, controlling holes, and using graphite and fused quartz. These choices help stop cracks and make the shroud last longer.

| Parameter | Benchmark Value |

| Thermal Shock Resistance | ≥5 |

| Al2O3 Content (%) | ≥45 to ≥60 |

| Cold Crushing Strength (MPa) | ≥20 to ≥22 |

| Bulk Density (g/cm³) | ≥2.35 to ≥3.40 |

Corrosion Resistance

Corrosion resistance keeps the ladle shroud safe from molten steel, slags, and quick heat changes. When you choose ladle shroud, think about how well it can fight these tough things. If the shroud rusts too fast, it can make the steel dirty and not last long.

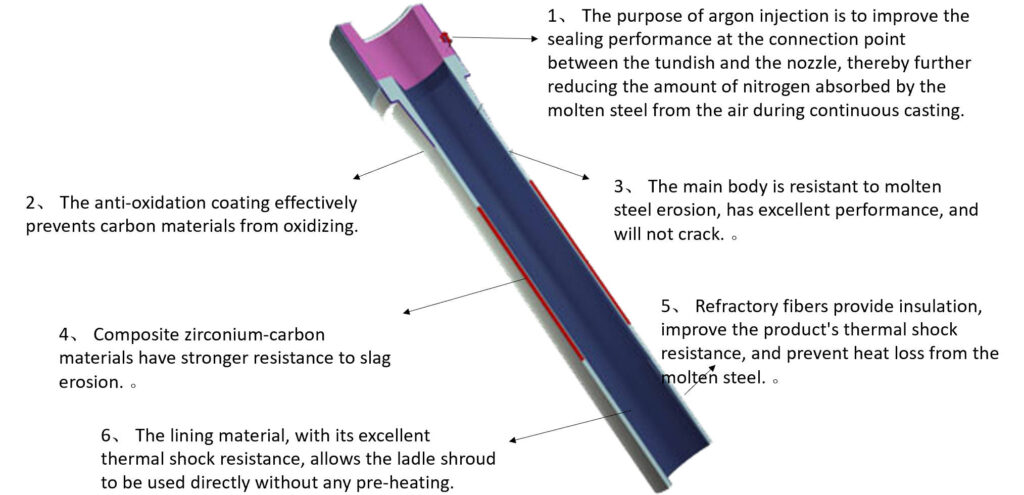

Materials like alumina-graphite and magnesia-carbon are very good at protecting the shroud. Alumina makes the shroud strong, and graphite helps with thermal shock resistance. Magnesia-carbon is great for fighting basic slags and molten steel. Zirconia-based materials also help stop chemical damage from slag.

Labs use different tests to check corrosion resistance. Here are some common tests:

| Test Type / Methodology | Description / Purpose |

| ASTM G48 | Checks for pitting and crevice corrosion in stainless steels and similar alloys |

| ASTM B117 | Uses salt spray to copy harsh environments |

| ASTM A262 | Tests if stainless steels can be attacked between grains |

You should ask your supplier for these test results to make sure the ladle shroud is right for you.

Mechanical Strength

Mechanical strength helps the ladle shroud handle stress when you move, install, or use it. When you choose ladle shroud, look for high cold crushing strength and bulk density. These things help the shroud not crack, chip, or break under pressure.

A strong ladle shroud keeps its shape and works well during long use. High mechanical strength means you do not need to replace it often. Look for shrouds with cold crushing strength of at least 20 MPa and bulk density above 2.35 g/cm³. These numbers show the shroud is tough and can handle steelmaking.

Material Selection

Material selection is very important when you choose ladle shroud. The best materials give a good mix of thermal shock resistance, corrosion resistance, and mechanical strength. Common materials are alumina, graphite, magnesia, and zirconia. Each one has special benefits:

| Material | Advantages |

| Alumina | Very good at handling heat and chemicals; resists wearing away. |

| Graphite | Makes thermal shock resistance better; stops cracks and wear. |

| Alumina-Graphite Composite | Strong and good with fast temperature changes. |

| Zirconia-Graphite Composite | Great at stopping corrosion and thermal shock; keeps temperature steady. |

| Fused Silica Composite | Best for thermal shock resistance; good for cold starts. |

You also need to think about how the ladle shroud works with different steel types and casting ways. Some steels, like low-carbon aluminum deoxidized steels, can clog the nozzle if the shroud is not right. Picking the right mix, like more alumina or adding zirconia, helps the shroud work better and need less fixing. Special shrouds, like scour-resistant or anti-oxidation types, help keep steel clean and reduce stops.

Note: Always pick the ladle shroud material that matches your casting needs and steel type. This helps the shroud last longer, stops problems, and gives better steel.

Supplier Evaluation

Picking the right supplier matters as much as picking the right ladle shroud. You want a partner who meets high standards and helps your business for a long time. Focus on three main things: certification, experience, and reputation.

Certification

Always check if your supplier has important certificates. These certificates show the factory follows strict rules for quality, safety, and the environment. Look for these main certificates:

- ISO9001: This means the supplier has a strong quality system.

- ISO14001: This shows the company cares about the environment.

- OHSAS18001: This proves the supplier keeps workers safe and healthy.

- CE: This mark means the product meets European safety rules.

- SGS: This is a trusted third-party inspection and testing certificate.

Tip: Ask your supplier to show you their certificates. This helps you avoid risky deals and makes sure you get good products.

Experience

Suppliers with many years in business often give better products and service. You can check how long the supplier has worked in this field. Here is a quick look at top ladle shroud makers in China:

| Manufacturer | Years of Experience |

| Puyang refractories | 29 |

| Vesuvius China | 20 |

The best suppliers in China have about 18.5 years of experience. If you pick a supplier with this much experience, you lower your risk and get better help.

Reputation

You need to know if other buyers trust your supplier. Online sites and industry reports help you check a supplier’s reputation. Volza is a good source for this. It gives you:

- Trade data, shipment records, and price analysis

- Dashboards to compare different suppliers

- Contact details for important people

- Tools to track competitors and market trends

You can use Volza’s free trial to start your research. A supplier with a strong reputation on trusted sites is more likely to give you good ladle shrouds and service.

Samples

Request Process

You should always ask for samples before you place a big order. Samples help you see the real quality of the ladle shroud. Most reliable China factories will send you samples if you ask.

Here is a simple process you can follow:

- Contact the supplier: Send a clear request for ladle shroud samples. State your steel grade and casting process.

- Share your requirements: Give details about size, material, and any special needs.

- Confirm sample cost and shipping: Ask if you need to pay for the sample or shipping. Some suppliers offer free samples, but you may need to pay for delivery.

- Set a timeline: Ask how long it will take to make and ship the sample.

- Track the shipment: Request a tracking number so you can follow the delivery.

Tip: Always keep records of your sample requests and supplier replies. This helps you compare different suppliers later.

Evaluation Points

When you get the samples, you need to check them carefully. Good evaluation helps you avoid problems in your steel plant.

Use this checklist to review each sample:

- Visual inspection: Look for cracks, chips, or uneven surfaces.

- Dimensions: Measure the length, diameter, and wall thickness. Make sure they match your needs.

- Material quality: Check the sample’s weight and feel. High-quality ladle shrouds feel dense and solid.

- Test certificates: Ask for lab reports on thermal shock resistance, corrosion resistance, and mechanical strength.

- Trial run: If possible, use the sample in a real casting process. Watch for leaks, breakage, or clogging.

| Evaluation Point | What to Check For |

| Appearance | No cracks or chips |

| Size | Matches your specs |

| Material | Dense, no weak spots |

| Performance | No leaks or early failure |

| Documentation | Includes test certificates |

Note: If a sample fails any test, you should ask the supplier for changes or look for another supplier. Quality at this stage saves you money and trouble later.

Pricing

Cost vs. Quality

When you look at ladle shroud prices from China, you will see many different prices. Some suppliers sell them for as little as $50 each. Others have special machines that cost up to $30,000 for one piece. The table below shows some price examples:

| Supplier / Product Description | Price Range (USD) | Minimum Order Quantity (MOQ) | Notes |

| Puyang refractories Group | 15,000 – 30,000 per piece | 1 piece | Specific price range provided |

| RHI China | Price: negotiation | 10 to 1000 pieces | No fixed price range |

| Alibaba listing – Continuous Casting Refractory Long Nozzle Ladle Shroud | 50 – 120 per piece | 1000 pieces | Sample price $120; no international comparison |

You should not just pick the cheapest option. More expensive ladle shrouds often use better materials and smart designs. These things help the shroud last longer and work better. For example, if you use high-purity alumina-graphite composites, the shroud can last about 25% longer. Special coatings and material mixes also help you spend less time and money on repairs.

Experts say you should think about both the first price and how much you save later. A higher price at the start can save you money if the shroud works well and lasts longer.

You can also check real stories and test results. These show that better materials and coatings are worth the extra money. Always ask for test results and proof before you buy.

Terms

Chinese suppliers usually let you pay in different ways. The most common way is Telegraphic Transfer (T/T). You pay 30% before they start making your order. You pay the other 70% after the shroud passes quality checks and before it ships. Some suppliers let you pay in three parts, like 20% first, 50% after making and checking, and 30% after delivery.

Letters of Credit (L/C) are another way to pay, especially for big or first-time orders. L/Cs are safer but cost more and take longer to set up. For small orders or samples, some suppliers may take PayPal or Escrow, but these are not common for big shipments.

Tip: Always get your payment terms in writing. Clear rules help you and the supplier avoid problems.

Support

Technical Help

You need strong technical help when buying ladle shrouds from a China factory. Good suppliers do more than just sell products. They help you fix problems and make your steelmaking better. You should find suppliers who give:

- Installation guidance: Easy steps or on-site help for setting up ladle shrouds.

- Troubleshooting: Quick help if you have leaks, cracks, or clogging.

- Customization advice: Help picking the right material or design for your steel and casting.

- Training: Some suppliers teach your team how to use ladle shrouds safely.

Tip: Ask if your supplier has a special technical team. Fast answers can save you time and money when making steel.

You can also see if the supplier gives remote help, like video calls or online chat. This lets you fix problems fast without waiting for someone to come.

Warranty

A good warranty means the supplier trusts their product. Always ask about the warranty before you order. Important things to check are:

| Warranty Feature | What to Look For |

| Coverage Period | At least 6–12 months after delivery |

| What’s Covered | Defects in materials or workmanship |

| Claim Process | Simple steps and fast response |

| Replacement Policy | Free replacement for faulty products |

Most good suppliers give a written warranty. This protects you if the ladle shroud breaks early or does not work right.

Note: Always keep your order papers and test results. These help you if you need to use the warranty.

Pick suppliers who stand by their products. This support helps you feel safe and avoid surprise costs.

When you choose ladle shroud from a China factory, you need to check both the product and the supplier. Focus on quality, reliability, and cost to get the best results. Use the steps in this guide as your checklist. You can reach out to certified suppliers or start your own evaluation process today. Careful choices help you avoid problems and keep your steelmaking safe.

FAQ

What is the minimum order quantity for ladle shrouds from China?

Most suppliers want you to buy at least 10 to 1,000 pieces. You should always ask your supplier about their MOQ before you order.

How do you verify the quality of a ladle shroud sample?

You need to look for cracks and check the size. You should also ask for test certificates. Always get lab reports for thermal shock resistance, corrosion resistance, and mechanical strength.

Can you customize ladle shrouds for different steel grades?

Yes, you can ask for special materials or designs. Good suppliers help you pick the right ladle shroud for your steel grade and casting process.

What payment methods do China factories accept?

Most suppliers take Telegraphic Transfer (T/T) and Letters of Credit (L/C). Some may let you use PayPal or Escrow for small orders or samples.

How long does it take to receive an order?

You usually get your order in 30 to 45 days after you pay. The exact time depends on how fast they make and ship your order.