1.1.1 Store demand :

- .ventilation drying

- .prevent package breakage ;

- .Not use the lining with torn pack;

- .Store period : one year from producing .

1.1.2 Check .

spot-check with magnet if any rarity including iron in the lining.

1.1.3.Construction for the bottom .

-1.

(1).Ramming the bottom at 450±10mm thick :

(2).Measure the distance from the roof to the bottom or note on the furnace wall ,in order to determine the construction thickness of furnace bottom materials.

-2.Charge

-2.1Check :

Nothing pollute into the furnace :

- .fragment of package ;

- .brings of operator ;

- .chip of worktop

-2.2.Charge

(1).Charge by thin layers ,inserting from upper layer into lower one with a steel fork, not to gather the big grain into a new layer

(2).Drop the lining lower and even , in case the piles and the Segregation of materials;

-3.Ramming

-3.1 Direction:

- .insert the fork downward vertically to the end ,not roiling from one side to another;

- .Don’t penetrate the insulating layer;

- .To ensure the ram density,the fork should be dropped even and force consistent.

-3.2 Proceed

- .from the around to the core, ramming orderly and gradually;

- .till harsh to insert with the fork and the wrist feels counter attack.

-3.3.Breakage

- .If the break happen during continue ramming ,the surface should be covered by a piece of plastic;

- .another ramming must be done after Scrapping away the surface and charge the material .

-3.4..Total

- .Two layers for bottom,

- .every layer should be 200-230mm thick;

- .every layer should be degassing with forks twice;

- .ram with bottom hammer once ;

- .After the first layer is tamped, the surface shall be scratched by the fork in order to excellent contact between two layers .

-3.5.Level the bottom

- .Scrap the floating layer of 30-50mm thick on the surface after construction for the hearth;

- .Survey the thickness of the bottom;

- .Cut away the redundant alarm line;

- .Scrap the lining of the joining part between the bottom and wall, and scratch this part;

- .Check with the gradienter to be sure the level of lining;

- . Touch the mould with the lining completely .

-4.Crucible mould

-4.1.Equip the crucible mould

- .method :the crucible moulds are installed according to the positioning and measurement are usual

- .the core of crucible must be fixed On the central axis of the sensoron to ensure the furnace wall has even thickness ;

-4.2.Demand for mold :

- .the iron board should be 8-12mm thick for the strength during ramming and sinter

- .the apperance of board should be no depression, rust, dry and clean;Weld joint and surface are rusted, polished and leveled;

- .There should be a certain angle between bottom and side wall to reduce the stress between furnace bottom and furnace wall during production.

- .the mould can be adopt after strictly testing for quality.

-4.3 .Place the mold

(1).Prepare the necessary supports and Special clip for correct positioning before placing the mold(three-point fixing);

(2).After placement, the standard state of the mold is horizontal, the circumference is parallel to the furnace wall, and the distance between the mold and the furnace body is the same.

(3).It is forbidden to move the mold after charge

1.1.4.the construction for furnace wall

-1.charge

- .After the crucible mould is put into the furnace, drop the lining into the furnace evenly in four directions (East, West, South and North)at the same time;

- .After the first layer of charge is poured evenly, insert it with electric fork twice ;

- .ramming to the wall and burned sinking, pour the remaining furnace material layer by layer, upto to parallel to the furnace mouth;

- .Cut off the internal support device of the crucible.

-2.Ramming

-2.1 ramming the furnace wall

(1).Put the Martin vibrator into the crucible stably with the rotating arm crane,

- .confirm that the wind pressure is normal (5-7 atmospheres),

- .start to ram the furnace wall;

- .with the ramming position rising, adjust the length of Martin vibrator ramming hammer to ensure that the ramming hammer can fully contact the crucible when it vibrates

Note:

- .when raise the Martin vibrator with the rotating arm crane,the operator should be careful ,to be sure that every part of crucible can be rammed fully.

- .for the crucible mould :

First three layer up the bottom ,every layer must be rammed for 25-30 minutes;

After these three layer, every layer should be rammed for 7-10 minutes;

Raise the ramming hammer to new layer every 150-200mm,

Stop ramming at the part 300 mm from the furnace mouth.

-2.2 ram the furnace mouth

(1).ram the furnace mouth with the mending fork and mending machine

(2).when ramming with the mending fork should drop evenly and force consistent in order to ensure the ramming density;

(3).after fininshing ramming with mending fork ,vibrate with repairing machine evenly and force consistent ,till the mouth be rammed compactly;

(4).Clean all materials up and down the furnace mouth after ramming the mouth;

(5).Put the protection washer at the furnace mouth after the first heat is smelted,

- Baking and sintering process of furnace body

After ramming the furnace lining can be baked and sintered ,in order to fully remove the moisture in the furnace lining and at high temperature sintered finally into a dense ceramic surface with high temperature strength

- Proceed of baking furnace body with electricity

2.1.1.fill the scrap

(1).the scrap includes Cutting head, return steel, test piece.etc;

(2).all of the scraps should be dry, clean and free of rust;

(3).Loadig dense,match the big pieces and small pieces ,pay attention not to “make bridges” ;

(4).Bulk material is dropped around the crucible wall, and small material is placed at the center of furnace bottom;

(5).length ≤400mm

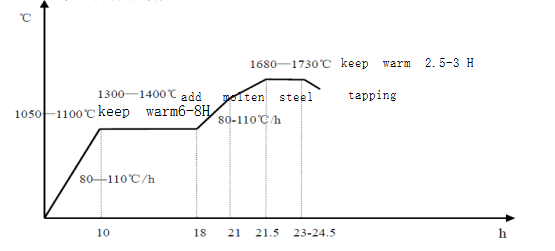

(6).To bake and sinter according to P2 (Sinter curve)

Note:

- .After heat preservation, the temperature rise shall be controlled at 80-110 ℃ / h;

- .When the temperature reaches 1100-1200 ℃, pull out the thermocouple;

- .After the calculated temperature reaches 1300-1400 ℃ the molten steel will be mixed according to the heating rate in the early stage.

2.1.2 First heat

(1).to bake furnace

(2).Fill the furnace with the scrap, make the furnace mouth fully sintered ;

(3).The whole crucible forms a uniform and dense sintering layer from top to bottom;

(4).Add natural gas burner above the furnace mouth;

(5).cover the roof to promote the temperature rise rapidly and even .

2.1.3 For 24-48 hours shutdown due to equipment failure

- .to check if there is the crack for the furnace body;

- .If there is serious crack, it should be repaired with green mud;

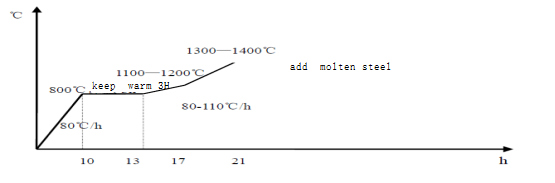

- .restart the cold furnace according to P3 (Sintering process curve of cold start);

- .Fill the scrap during the hot-stopping ,at the same time bake with natural gas , in order to keep the temperature .

2.1.4 For surpass 48 hours shutdown due to equipment failure,restart according to following orders:

- .To expand the steel volume at the last heat after planning to shutdown,drop the steel molten to the position which is 220mm from the upper mouth;

- .tapping temperature is 1650-1680℃,preserve heat for 30 minutes;

- .Clean molten steel and slag after tapping;

- check the working condition of the furnace body

-1. Check whether there is water leakage at the relevant position of the furnace body

-2.Check whether the water pressure at all places meets the requirements,

-3.check whether the alarm device is in good condition

- ,ensure to meet the intermittent production conditions (thickness of furnace wall is than 90mm, no obvious defects)

2.3. the construction of the furnace wall

2.3.1 the sinter layer

- .In order to ensure forming the sinter layer for every heat ,each kind of steel should be sampled at more than 1630℃, at least fill with steel molten fully every 5 heats ;

- .for sintered lining, the thickness of the sinter layer is 30% of the whole lining ,should be 10mm-15mm thick;

-1.The sintering layer is too thin to withstand the mechanical impact and erosion of molten steel during charginge;

-2. if the sintering layer is too thick, it may crack completely.

2.3.2.The transition layer accounts for about 30% – 40%;

2.3.3 the loose layer as buffer accounts for 20% – 30%.

Standard for furnace body down line

- .Thickness for the lining is less than 90mm,or can’t meet the producing requirement for next heat.

- .Calibrate and record the thickness of loose layer (≥30mm) after the down line of furnace body

2.4 In order to prevent the impact of iron and steel materials on the refractory of furnace lining, the furnace body shall be protected by the protective cover for the furnace mouth and iron plate when loading iron.at the same time charge the iron according to the method of less amount and more times.

2.5 During the smelting ,if the melting line has formed,when we charge it is necessary to bake above the furnace (especially for the wet steel or scrap) ,the iron and steel must be dry ,in case the splashing accident happen because of loading the humid or cold material.