Recycling slide gate plates to save costs and reduce waste

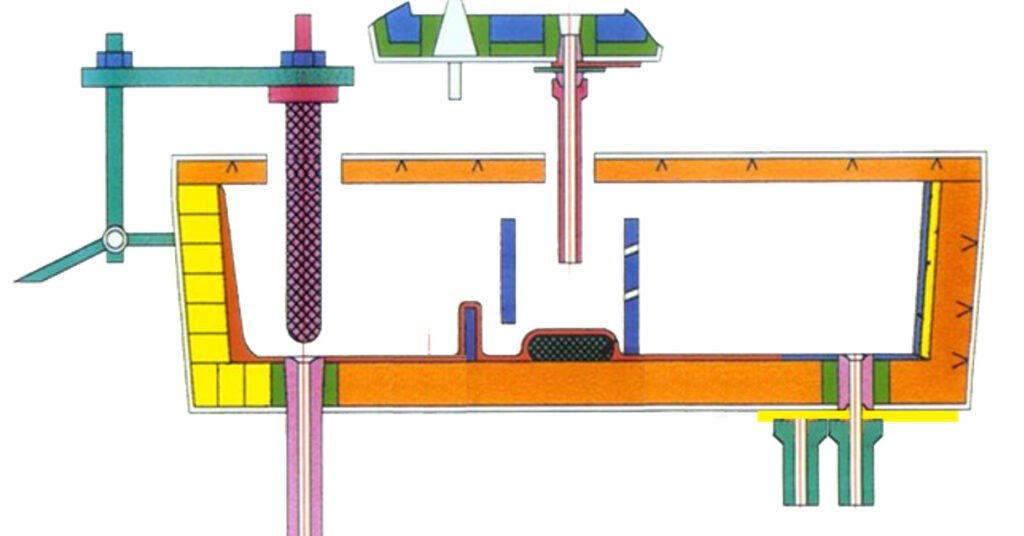

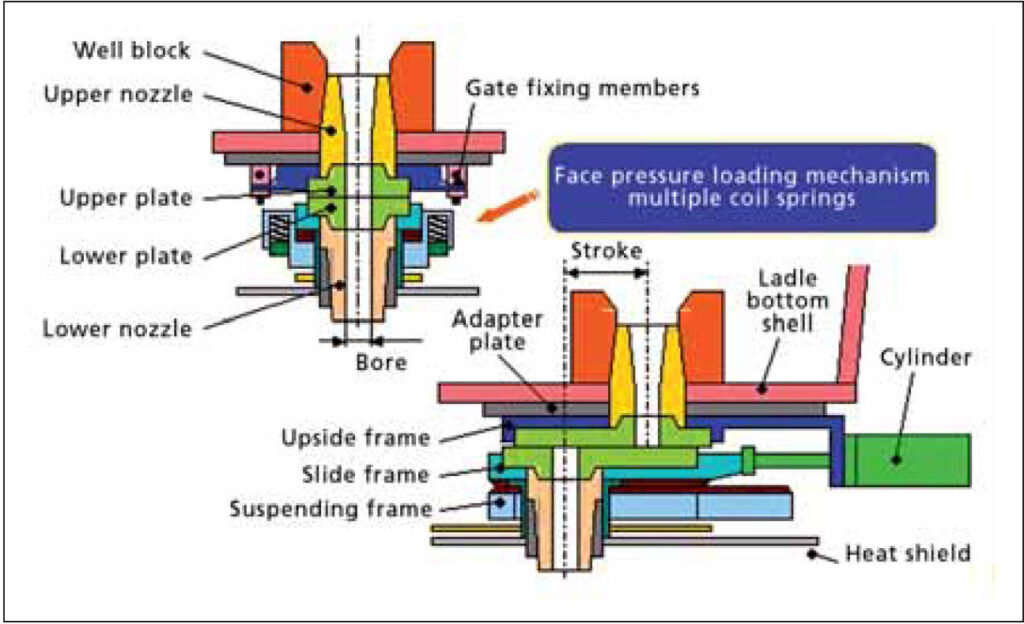

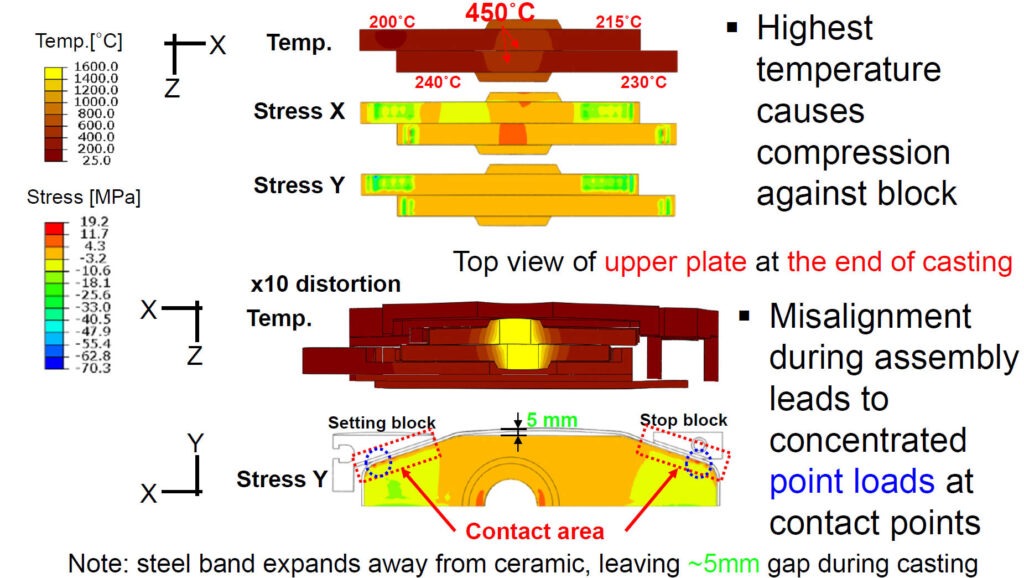

You have more problems in steelmaking because raw materials are harder to get. Recycling a slide gate plate lets you save money and help the earth. This process keeps important resources being used, which helps a circular economy. When you recycle, you make less waste and lower your effect on the environment. Every time you […]