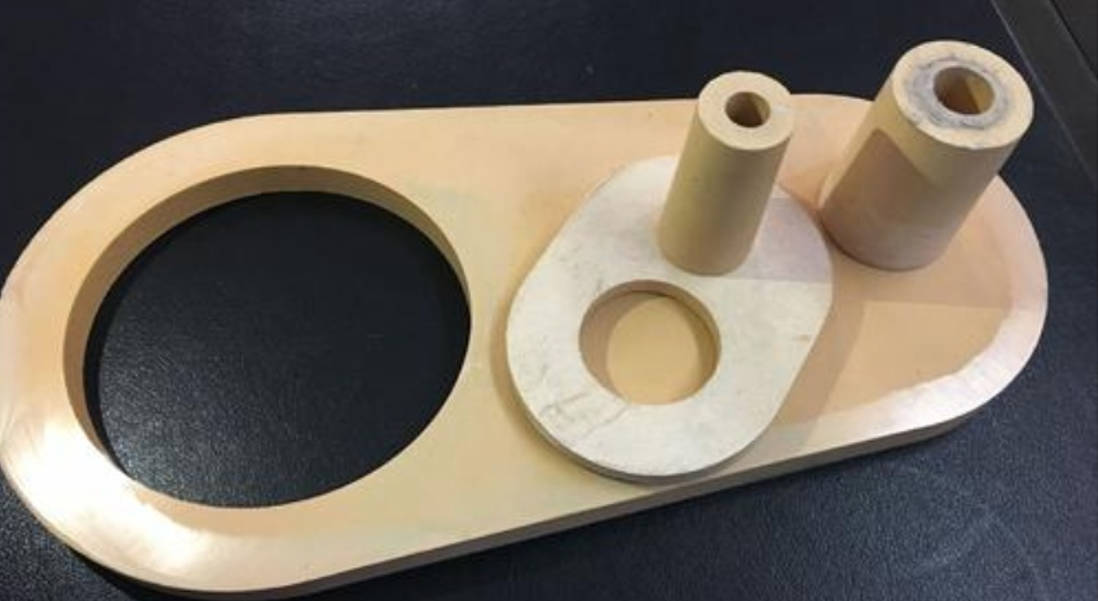

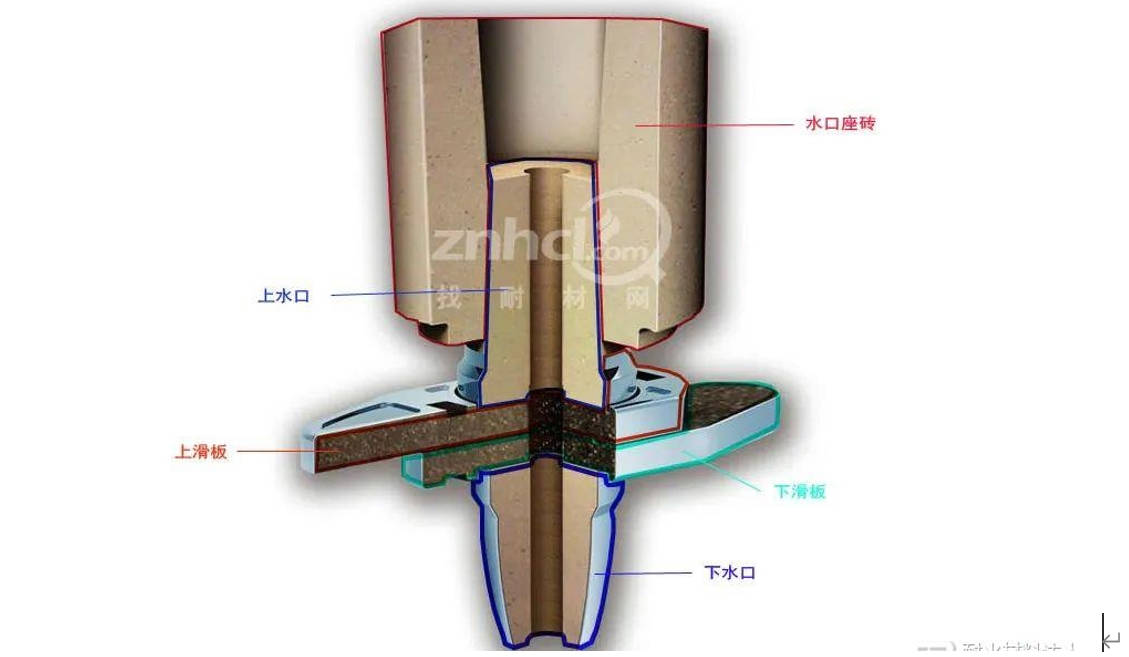

Before discussing the causes of damage to the ladle sliding plate, let’s first take a look at the sliding mechanism of the ladle. The schematic diagram of the tundish and sliding plate structure is shown below:

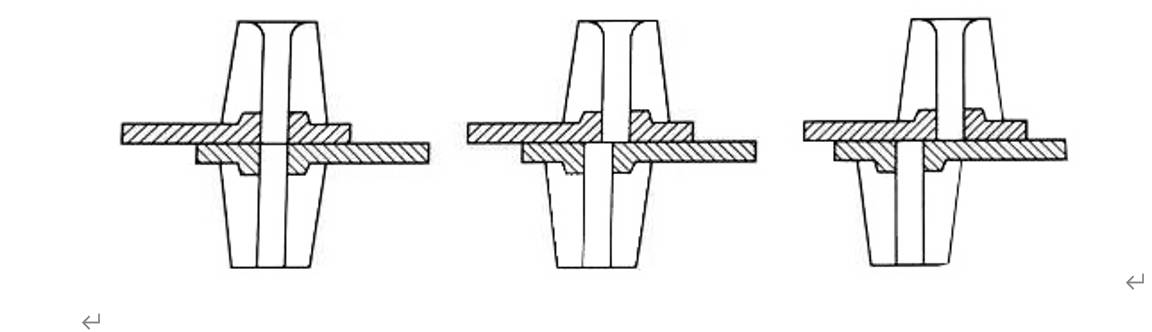

A steel ladle sliding nozzle consists of a sliding mechanism, an upper nozzle, a sliding plate, and a lower nozzle. The sliding plate is comprised of an upper and a lower plate; the shape of the sliding plate depends on the requirements of the mechanism. If the dimensions of the upper and lower plates are the same, they can be used interchangeably; if the dimensions differ, they cannot be used interchangeably. The upper sliding plate is fixed, while the lower sliding plate is movable. The movement mechanism can be either linear reciprocating or rotary.

A linear reciprocating sliding gate mechanism typically consists of a base plate, a fixed frame, a movable frame, and a sliding box. The lower sliding plate is mounted within the sliding box and is held in place by a spring; the gap between the upper and lower sliding plates controls the flow of molten steel. The sliding plate is usually moved reciprocally by a hydraulic cylinder or an electric actuator to regulate the flow rate of the molten steel.

The erosion mechanism of the slide gate plate

1.Thermo-mechanical erosion

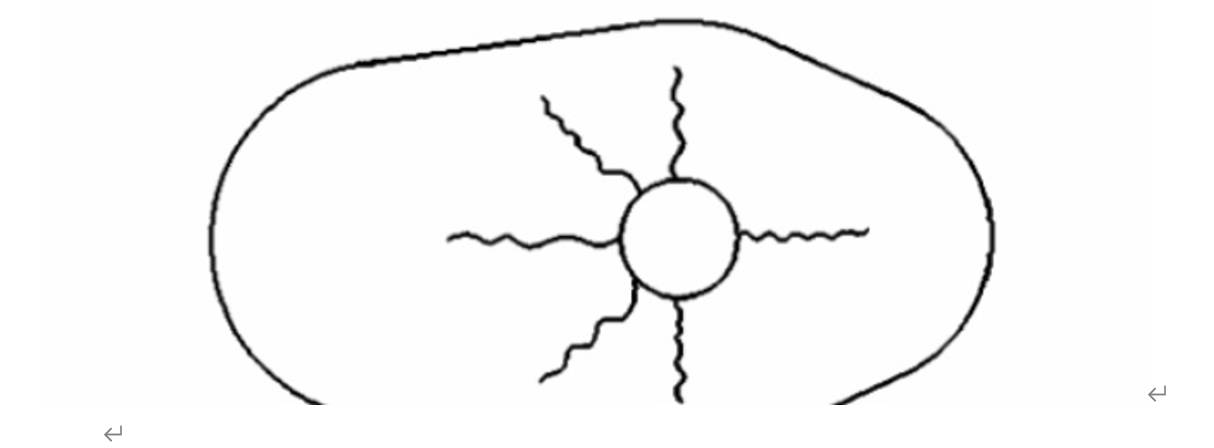

During operation, the sliding plate first experiences thermo-mechanical damage. Before use, the temperature of the sliding plate is very low. During the casting process, the internal hole of the sliding plate suddenly comes into contact with molten steel at high temperatures (1600°C), resulting in severe thermal shock (a temperature change of approximately 1400°C). This generates tensile stress exceeding the strength of the sliding plate around the casting hole, leading to the formation of radial microcracks originating from the casting hole.

The presence of cracks facilitates the diffusion, accumulation, and penetration of foreign impurities, further accelerating chemical erosion. Simultaneously, the chemical erosion reaction promotes the formation and propagation of cracks, creating a vicious cycle that leads to the gradual enlargement and damage of the wear plate’s casting pores. Furthermore, the scouring action of high-temperature molten steel damages the refractory materials in contact with the steel, causing spalling and chipping.

2 thermochemical erosion

Thermochemical erosion is another major cause of slide plate damage. During use, the refractory material of the slide plate comes into contact with high-temperature molten steel and slag, undergoing a series of chemical reactions that cause chemical erosion. Different steel types have different chemical erosion mechanisms on the slide plate; therefore, selecting the appropriate material for the slide plate based on the specific operating conditions can extend its service life and reduce refractory material costs. The chemical mechanisms of damage in Al₂O₃-C and ZrO₂-Al₂O₃-C slide plates are:

(1) Carbon oxidation. Graphite and carbon oxidation occur mainly through two pathways: one is the oxidation of carbon by oxygen in the molten steel, especially in high-oxygen steel, forming pores, allowing iron to penetrate and causing steel slag to adhere to the surface; the other is the oxidation of carbon by oxygen in the air, forming low-melting compounds that further erode and penetrate along the pores.

(2) Mullite decomposition. Mullite decomposes to varying degrees during use, transforming into columnar and granular corundum crystals, forming a porous structure. This disrupts the original dense eutectic structure of mullite and diopside, resulting in a looser structure, deteriorated microstructure, and significantly reduced strength and corrosion resistance, accelerating slide plate damage.

(3) Erosion by (Mn) and (Fe). SiO₂ in the slide plate reacts with FeO and MnO in the steel and slag to form low-melting point minerals 2FeO·SiO₂ (1205℃) and MnO·SiO₂ (1291℃). (4) Damage by (Ca). Al₂O₃·SiO₂ reacts with CaO in the steel and slag to form low-melting point compounds 2CaO·Al₂O₃·SiO₂ (1327℃) and 12CaO·7Al₂O₃ (1392℃).

3. operational factors affect slide gate plate

Operational factors that contribute to damage of sliding plates can be categorized into three main aspects. Firstly, improper installation of the sliding plate. If the sliding plate is installed incorrectly on the sliding mechanism, causing warping or loosening of the clamp, significant external stress will be generated during use, ultimately leading to overall damage of the plate. Secondly, improper flow control during casting. During the casting process, if the flow control is not properly managed (e.g., excessive flow rate or frequent adjustments), it can cause wear, erosion, and slag entrapment on the working surface of the sliding plate. Manual operation, in particular, can lead to significant damage due to human error. Thirdly, improper oxygen lance operation. When molten steel flow stops during casting, oxygen lancing of the ladle nozzle is necessary. Improper oxygen lancing can cause severe erosion. Common improper practices include:

-

- blowing oxygen before the sliding plate is fully aligned, causing direct impact of oxygen on the working surface;

-

- blowing oxygen when the refractory lining has not completely melted, leading to prolonged oxygen exposure;

-

- oxygen lance not parallel to the flow path, causing erosion of the plate’s edge;

-

- improper ladle turnover time, leading to temperature drop and thermal shock;

-

- improper refractory material composition, uneven mixing, or impurities in the refractory material. Since sliding plates are repeatedly exposed to high-temperature molten steel, they require specific properties to prevent molten steel leakage during casting. These properties include:

(1) a smooth and flat sliding surface;

(2) high mechanical strength;

(3) strong resistance to molten steel and slag erosion;

(4) low adhesion of molten steel. Many researchers and steel mills have developed measures to improve the lifespan of sliding plates, some of which are shared in this article. Firstly, the material of the sliding plate is crucial. Materials with corundum, mullite, or zircon as the main crystal phase and carbonaceous materials as binders are commonly used. These materials have high thermal conductivity, low thermal expansion coefficient, and strong resistance to thermal shock.

During the installation of the sliding gate, ensure that the areas around the water inlet and outlet are thoroughly cleaned, and that the inside of the panel frame and the mechanism door are free of any debris or residue. The panel cannot be used if it shows any signs of deformation, cracking, or other irregularities.

During nozzle replacement in a steel ladle, it is strictly prohibited to clean the nozzle using oxygen flow from the inside out. The oxygen cleaning process must be performed quickly; if any abnormalities are detected, the slide plate must be replaced.

Advantages and disadvantages of different slide gate plate materials commonly used

1. High-alumina slide gate plate disadvantages:

(1) Poor resistance to erosion; severe erosion of the sliding surface and pouring spout.。

(2) Poor thermal shock resistance; prone to cracking during use.。

2. Aluminum-carbon slide gate plate

Aluminum-carbon sliding plates have evolved into two types: unburned and burned. To enhance their resistance to erosion and thermal shock, unburned aluminum-carbon sliding plates incorporate synthetic mullite, cordierite, and silicon carbide materials in the granules, and alumina and silicon carbide in the matrix.

However, sliding plates made of this material gradually exhibit problems such as low heat resistance, severe wear on the sliding surface, and poor resistance to cracking. The disadvantages of burned aluminum-carbon bricks include poor resistance to thermal shock, inability for repeated use, and susceptibility to carbon oxidation and low corrosion resistance during use.

3. Aluminum-zirconium-carbon slide gate plate

The aluminum-zirconia-carbon sliding plate was developed based on the sintered aluminum-carbon sliding plate. This type of sliding plate is made from a low-expansion Al2O3-SiO2-ZrO2 system material, forming a refractory material with tetragonal zirconia, mullite, and corundum as the main crystal phases, and carbon as the binder. While aluminum-carbon sliding plates have quite good performance and applicability, cracking and wear of the sliding surface during repeated use are key factors limiting their service life.

Carbon-bonded aluminum carbide and aluminum-zirconium carbide sliding plates are commonly used as sliding plate materials in steel mills both domestically and internationally. However, these two types of sliding plates have poor resistance to calcium erosion when casting calcium-treated steel, and are therefore unsuitable for casting calcium-treated steel, Al/Si-killed steel, and other similar types of steel.

4. Magnesium carbide and spinel carbide sliding plates

Magnesia-based sliding plates were first used in Europe. Because magnesium oxide has good resistance to mechanical stress and chemical erosion, it partially meets the requirements for casting calcium-treated steel and high-oxygen steel. However, the thermal expansion coefficient of magnesia is high, leading to thermal spalling during steel casting, and its thermal shock resistance needs improvement. Spinel-carbon sliding plates are refractory materials characterized by a spinel (magnesium aluminate) as the main crystalline phase, with a ceramic-carbon composite structure. The thermal expansion coefficient and modulus of elasticity of spinel are lower than those of magnesia, and its thermal shock resistance is better. However, spinel undergoes a slow chemical reaction with calcium in the steel, forming low-melting compounds that affect its service life.

5. Zirconia based slide gate plate

Zirconia based sliding plates manufactured using hot-pressing technology exhibit high high-temperature strength, low apparent porosity, and small pore size, resulting in excellent resistance to erosion by molten steel when used in ladle linings.

Zirconia material has excellent high-temperature performance, but due to its cost and other factors, in industrial applications, composite sliding plates are typically made by embedding zirconia rings around the casting holes of aluminum-carbon plates.