The ladle shroud has evolved from a simple refractory tube into a multifunctional, highly engineered device that plays an essential role in clean steel production. As continuous casting (CC) technology has advanced, the requirements for process stability, steel cleanliness, and operational safety have increased significantly. In response, the ladle shroud has undergone substantial development in design, materials, and functional capability. Today, the shroud is not only responsible for isolating the teeming stream from atmospheric contamination—it also contributes directly to fluid flow control, slag carry-over detection, multiphase flow optimization, and emerging practices such as stream heating and additive injection.

This article provides a comprehensive technical review of the key advances in ladle shroud technology, based on the most recent industrial and scientific research.

1. Evolution of Ladle Shroud Functionality

1.1 From Mechanical Shielding to a Clean-Steel Device

Originally introduced to prevent the reoxidation of molten steel during teeming, early ladle shrouds—typically made from fused silica—could serve only 2 to 3 heats. Modern shrouds, manufactured from high-performance alumina-graphite composites and coated with erosion-resistant layers such as zirconia or carbon-free linings, now operate reliably for dozens of heats.

The primary motivations driving the evolution of ladle shrouds include:

- Minimizing atmospheric air ingress and reoxidation

- Improving tundish flow stability

- Reducing inclusion generation

- Enhancing casting efficiency

- Extending refractory service life

As a consequence, the ladle shroud has become a key interface between the ladle’s flow control system and the tundish metallurgy environment.

2. Advances in Shrouding Performance

2.1 Understanding Air Ingress and Stream Contamination

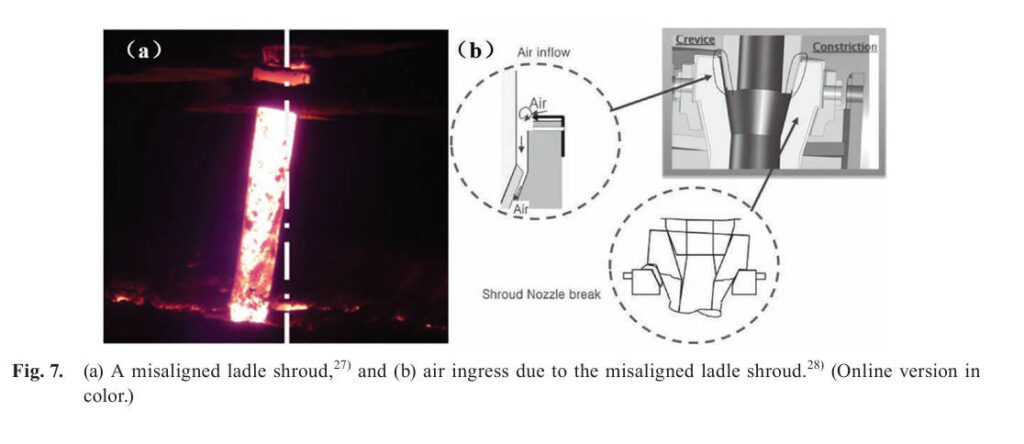

Even with mechanical shrouding, air infiltration can still occur through micro-crevices at the junction between the collector nozzle and the shroud. Fluid dynamic modeling shows that negative pressure generated by high-velocity molten steel inside the shroud can draw air inward unless proper sealing techniques are used.

The primary mechanisms of improvement include:

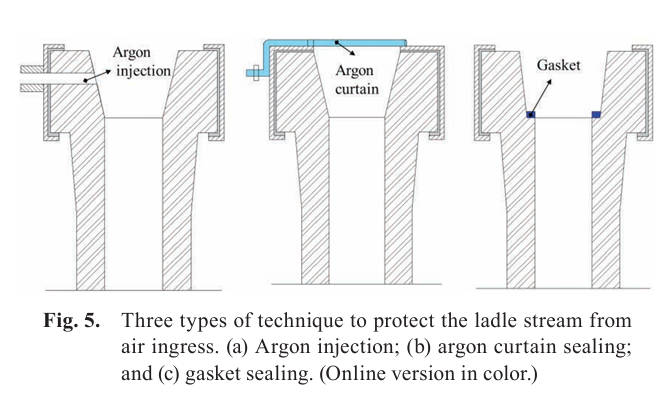

(1) Internal Argon Injection

Argon injection at the shroud neck helps:

- Minimize pressure differential between the interior and ambient atmosphere

- Reduce oxygen ingress

- Promote the formation of fine bubbles beneficial for inclusion flotation

(2) Argon Curtain Sealing

A ring-shaped jet of inert gas forms a protective argon atmosphere around the shroud joint to displace residual air.

(3) High-Quality Gasket Sealing

Refractory or fiber-reinforced gaskets (annular or frustum-shaped) provide mechanical sealing between the collector nozzle and the shroud, significantly reducing crevice leakage.

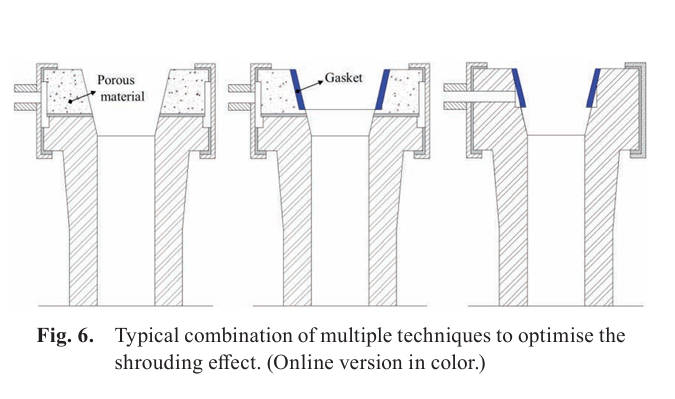

A combination of these techniques is applied in most modern caster operations.

3. Structural Advances for Flow Control

As tundish metallurgy becomes more sophisticated, the ladle shroud now acts as an active flow control device that determines:

- Teeming jet velocity

- Turbulence kinetic energy (TKE)

- Pouring zone stability

- Tundish open eye (TOE) behavior

- Inclusion transport and floatation

3.1 Industrial Ladle Shroud Designs

(1) Conventional Ladle Shroud (CLS)

A straight cylindrical bore, simple to manufacture but characterized by:

- High-velocity outlet jet

- Higher turbulence in pouring zone

- Increased risk of slag entrainment

- Higher sensitivity to partial slide gate openings

(2) Trumpet Ladle Shroud (TLS)

Now widely adopted, TLS designs feature an enlarged bore at the outlet, either through:

- A gradual trumpet expansion, or

- A divergent chamber followed by a wide straight section

Benefits include:

- Significant reduction in exit velocity

- Reduced turbulence and splashing during ladle opening

- Minimized slag–steel emulsification

- Lower incidence of nozzle clogging

- Improved tundish surface stability

- Increased inclusion flotation efficiency

Field studies show TLS provides a notably calmer tundish bath compared to CLS, especially during transient operations such as ladle change.

3.2 Advanced Shroud Concepts Under Exploration

Several novel geometries have been investigated in laboratory and simulation environments:

Swirling Ladle Shroud (SLS)

- Generates a swirling flow to promote inclusion flotation and turbulence dissipation

- Challenges: refractory erosion at blade structures and manufacturing complexity

Dissipative Ladle Shroud (DLS)

- Features multiple chambers to break down kinetic energy

- Proven effective in simulations but difficult to produce industrially

Two-Side-Port Shroud

- Similar to mold SEN design; releases steel laterally at reduced velocity

- Useful in multi-strand symmetric tundishes

Biased and Bending Nozzles

- Promote directional flow for asymmetric tundishes

- Risk of biased forces leading to air ingress and structural erosion

While promising, these designs require industrial validation before widespread adoption.

4. Operational Advances

4.1 Argon Injection Optimization

The size and behavior of argon bubbles introduced at the shroud neck are critical. Fine bubbles (<1 mm) enhance inclusion removal, whereas larger bubbles (3–5 mm) contribute to slag eye formation due to upward buoyant plumes.

Key influences on bubble size include:

- Gas flow rate

- Liquid flow velocity

- Nozzle geometry

- Argon supply pressure

Mathematical modeling (LES, VOF) is increasingly used to predict multiphase interactions.

4.2 Addressing Misalignment

Misalignment between the shroud and collector nozzle produces:

- Biased jet flow

- Eccentric tundish open eye

- Enhanced risk of slag entrainment

- Gasket failure and air leakage

Advanced technologies include:

- Hydraulic manipulators with torque sensing

- Self-locking shroud holding devices

- Three-plate slide gate systems

- Impact pots in tundish to moderate biased turbulence

Proper alignment significantly enhances both shrouding and flow performance.

4.3 Influence of Slide Gate Opening

Partially opened slide gates create asymmetrical inlet flow that:

- Generates strong vortices inside CLS

- Shifts the outlet flow centerline

- Increases risk of biased turbulence in tundish

TLS mitigates some of this due to better energy dissipation at the outlet.

5. Functional Extensions: Beyond Flow and Shrouding

5.1 Vibration-Based Slag Carry-Over Detection

With visual detection impossible during submerged teeming, vibration sensors installed on the manipulator detect changes in frequency and amplitude caused by slag entering the flow.

Advantages include:

- Early detection before vortex breakthrough

- Low maintenance

- High reliability when combined with algorithmic signal processing

This technique is increasingly replacing electromagnetic detection in some plants.

5.2 Stream Heating via Induction

A new innovation is induction heating around the ladle shroud, offering:

- Compensation of temperature loss during ladle change

- Reduction of superheat requirements

- Improved stability in low-superheat casting

Engineering challenges remain, such as cooling, mechanical protection, and integration with shroud support structures.

5.3 Additive Injection through Shroud

The ladle shroud’s intense turbulence makes it a suitable point for finely dispersed additive introduction (e.g., Fe-B powders), achieving high mixing efficiency. While still experimental, the concept holds promise for alloying or microstructure control at the tundish stage.

6. Advances in Shroud Materials and Service Life

Improvements in refractory materials have dramatically increased shroud durability. Key developments include:

- Alumina-graphite composites with optimized carbon bonding

- ZrO₂-rich coatings resistant to slag corrosion

- Carbon-free inner linings to reduce decarburization

- Nano-scale additives (MgAl₂O₄, CNTs, Al₂O₃) for enhanced toughness

- Outer foaming insulation layers to minimize thermal shock

- Increased wall thickness in submerged section

- Improved cleaning technologies such as shower cleaning

These technologies extend ladle shroud life to 30–40+ heats, significantly reducing operating cost.

Conclusion

The ladle shroud is no longer a passive protective tube; it has become a critical functional device in tundish metallurgy, offering integrated benefits in:

- Stream protection

- Flow control

- Gas–liquid–slag multiphase optimization

- Slag detection

- Thermal stability

- Material conditioning

Ongoing research into multiphase flow modeling, smart control systems, advanced refractory materials, and novel geometries continues to push the boundaries of shroud performance. As steelmaking moves toward higher productivity, lower emissions, and stricter quality requirements, the ladle shroud’s role will only grow in significance.