Wherever furnace construction and operating conditions permit, refractory linings are typically constructed with brick of standard sizes and shapes. Standard materials cost less than larger, more intricate shapes and frequently are more serviceable. They are also more accessible, in that they are likely to be routinely stocked by the manufacturer.

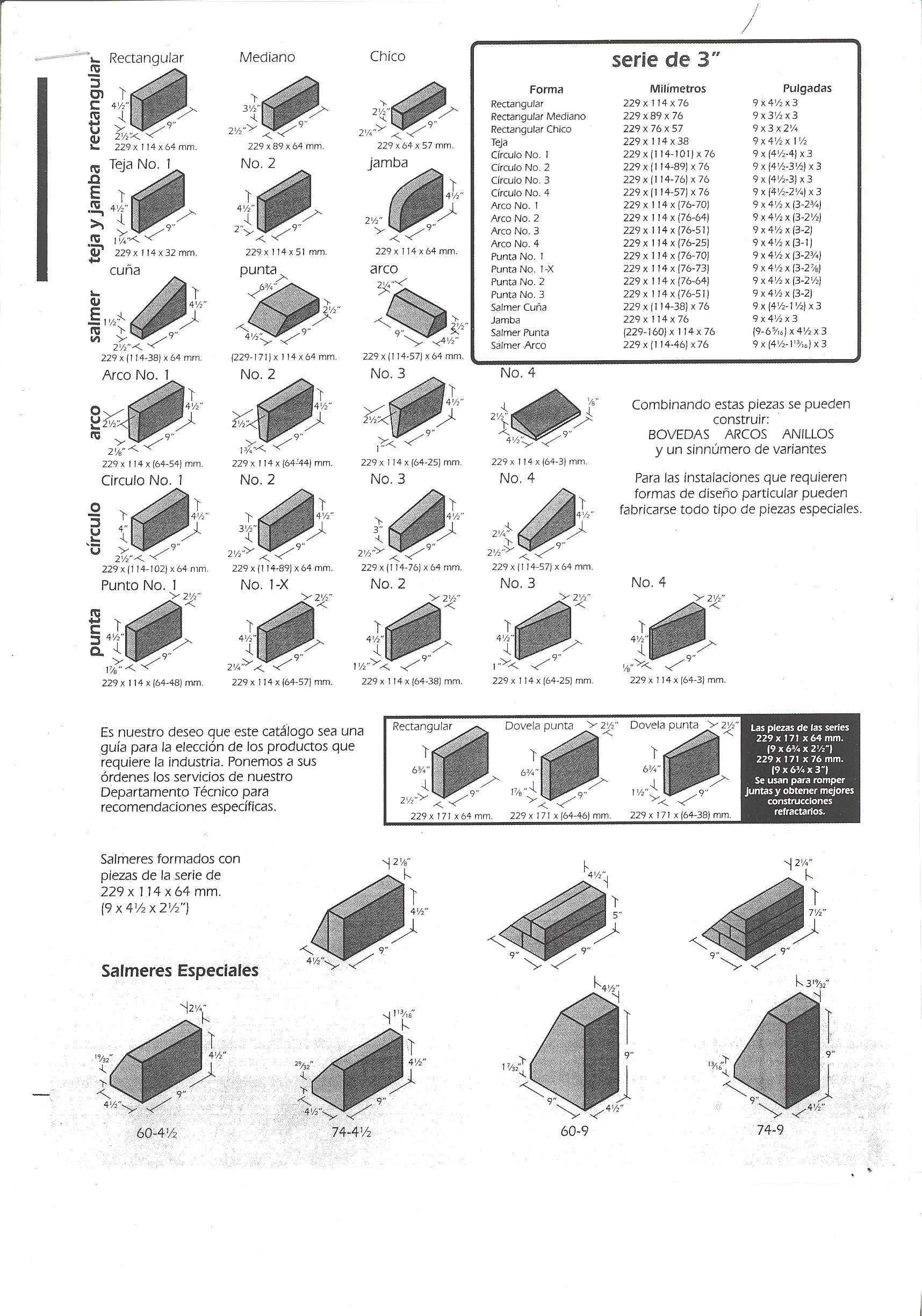

The most widely used standard size for all types of refractory brick is 9 x 41/2 by 3 inches. Most brands offer larger sizes, as well. Special shapes, such as skewback brick, are important in the construction of numerous kinds of furnaces having sprung arches.

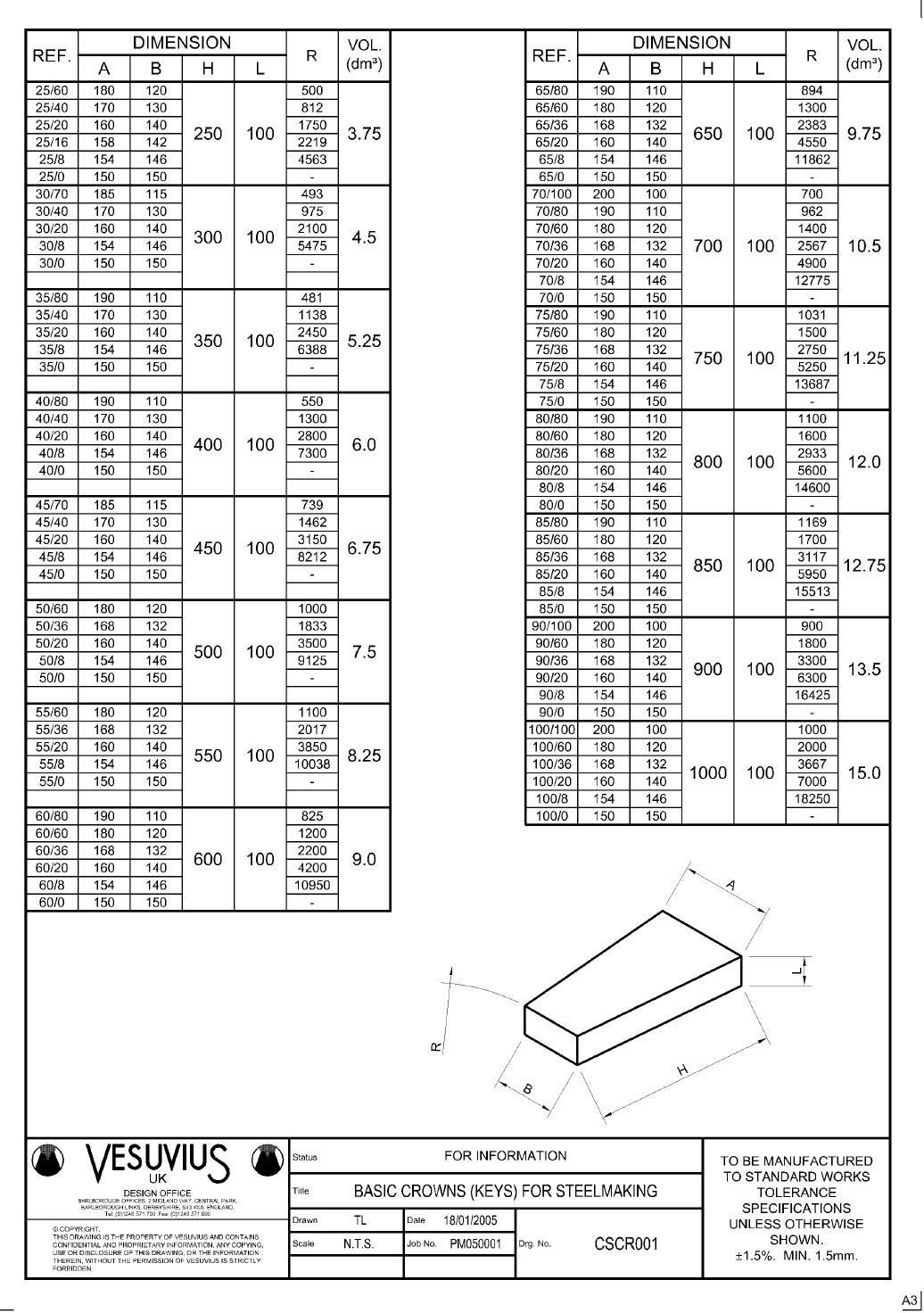

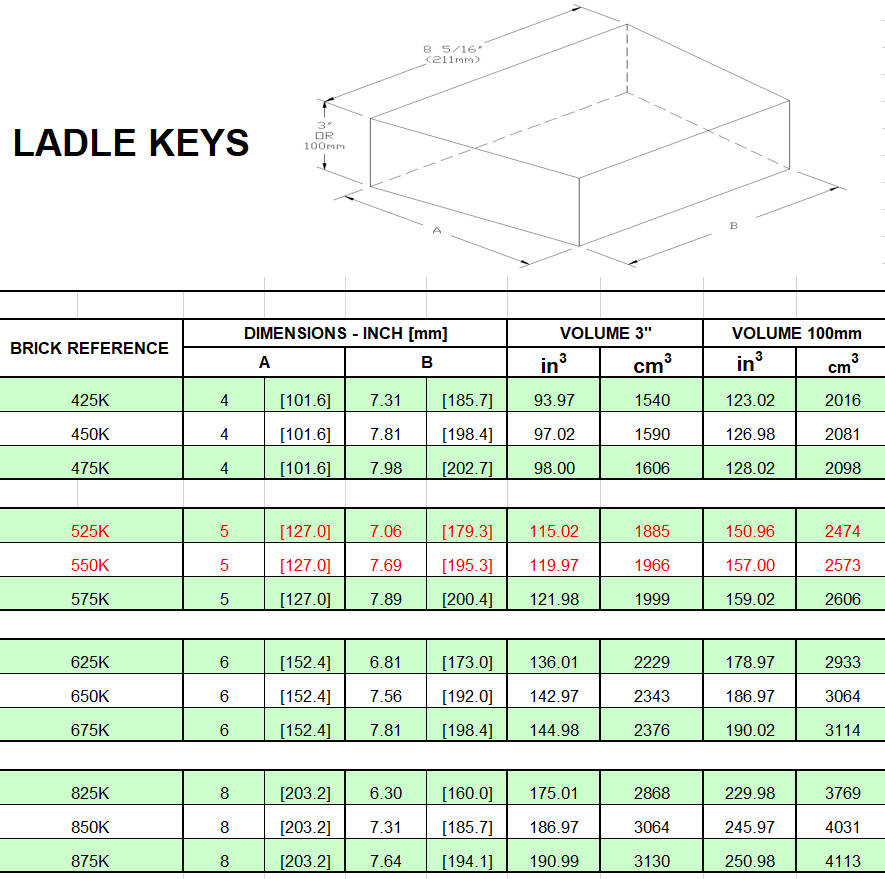

This section provides a comprehensive listing of standard brick sizes and shapes for a variety of furnace applications, as well as ring and arch combinations for standard size refractory brick. Additional sections address special shapes such as semi-universal ladle brick, brick counts for rotary kilns and rotary kiln brick shapes, including ISO, VDZ and CR two-shape systems for combination linings. Together, offer refractory users a ready reference of information governing furnace refractory lining and construction.

Refractory brick are classified on the basis of their form as Rectangular Shapes or Special Shapes.

Rectangular Sizes are brick of relatively simple design, with certain definite shapes, that are marketed in sufficient amounts to permit quantity production. Rectangular sizes are preferred wherever furnace con-struction and operating conditions permit. These brick cost less than longer and more intricate shapes.

Special Shapes are refractory brick of special design of either sim-ple or intricate form. Some special shapes may be considered as mod-ifications of rectangular tile having the same overall dimensions.

For initial orders of special shapes, drawings showing complete details of the shapes, as well as their assembly in the furnace, should be included. The drawing and shape numbers should be provided on all subsequent orders.

In high-temperature industrial furnaces, refractory bricks play a crucial role in maintaining structural stability, thermal efficiency, and operational safety. These specially designed bricks are made from heat-resistant materials that can withstand extreme temperatures, mechanical stress, and chemical corrosion inside steelmaking, glass, or cement furnaces. To achieve the best lining performance, various brick shapes and sizes are used in different parts of the furnace according to structural and thermal requirements.

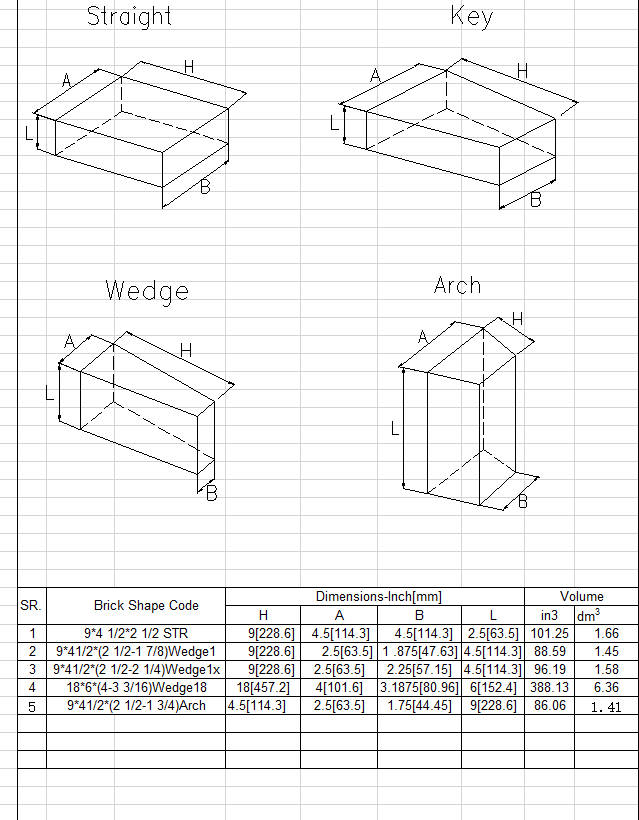

Among the most common shapes are standard straight bricks, which are rectangular and used for flat wall and floor sections. These bricks are the basic building units in almost every refractory structure. However, when the furnace design involves curved surfaces or domed roofs, specially shaped bricks such as key bricks and arch bricks are required to ensure a precise fit and strong mechanical interlock.

Key bricks are designed with a wedge-shaped profile. Their width or thickness gradually changes from one side to the other, allowing them to be tightly fitted together in circular or arch constructions. When installed, the taper of the key bricks creates compressive force within the lining, enhancing stability and preventing collapse even under high thermal expansion. Key bricks are often used in rotary kilns, ladle covers, and dome-type furnace roofs, where maintaining a uniform and tight structure is essential.

Arch bricks are another important type used mainly for building vaulted furnace roofs or tunnels. Their curved or tapered sides allow them to form a strong arch structure that can bear heavy loads without requiring metal supports. The arch design distributes stress evenly and reduces the risk of brick displacement. In practice, arch bricks come in several types—such as end bricks, crown bricks, and side arch bricks—each tailored for a specific position within the dome or arch. Accurate shape and size control are critical, as even a small dimensional error can cause misalignment or weak joints during construction.

In addition to key and arch bricks, many furnaces use wedge bricks, skew bricks, and special-shaped blocks designed according to the furnace’s geometry. Modern refractory engineering often involves custom-made bricks produced from 3D drawings or CAD models to ensure a perfect fit in complex designs. These custom shapes minimize joint gaps, improve lining life, and reduce heat loss.

Understanding these brick shapes and their arrangement helps explain why refractory construction is both an art and a science. Each shape serves a purpose—not only to resist heat but also to distribute stress, support structural loads, and maintain tight joints under thermal cycling. The photos that follow illustrate several common refractory shapes, showing their dimensions, cross-sections, and applications. By studying these examples, readers can better appreciate how different brick designs work together to form a durable and efficient furnace lining.