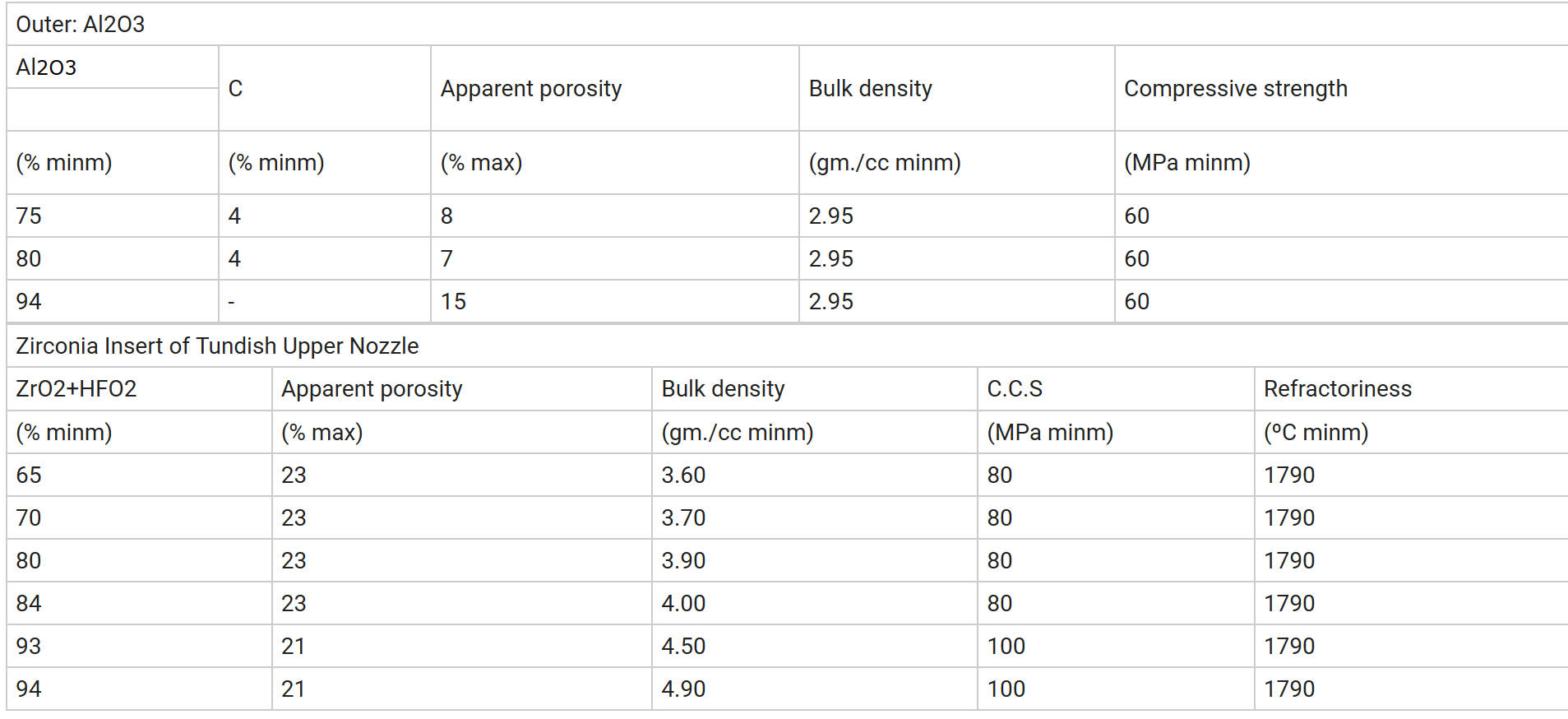

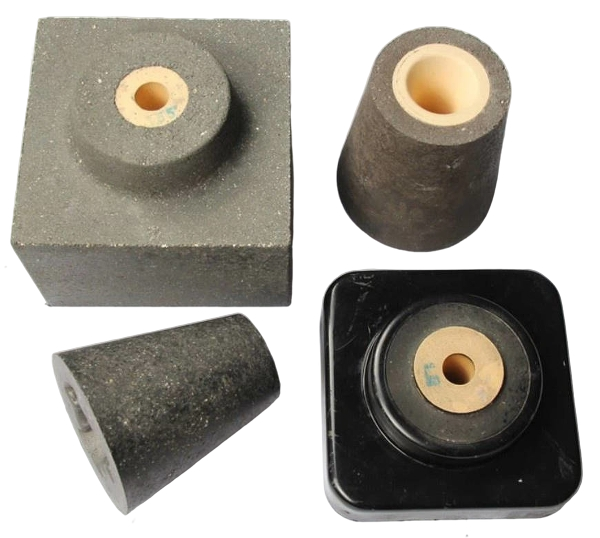

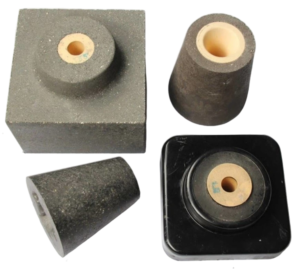

Tundish metering nozzles consist of an upper nozzle (a stationary nozzle) and a lower nozzle (exchangeable nozzle).

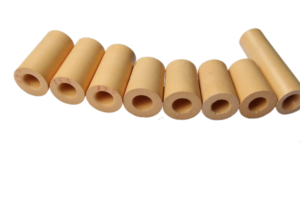

The Upper Nozzle is located within the tundish lining and transfers the molten steel to the controlling exchangeable nozzle, which determines the steel flow. Upper nozzle incorporates an ultra-high-density high density zirconia insert. The zirconia insert provides excellent erosion resistance and extended casting sequence times.

Lower nozzle (exchangeable) is located within the assembly that is fixed to the bottom of the tundish. The design of the lower nozzle can vary according to the system manufacturer. Zirconia insert can be supplied for in-site assembly into metallic holding blocks, where cementing, grinding, size banding, and on-site drying are required before use.

It was manufactured by the cast process of fine fine-grain alumina method and the press process.Upper nozzle and lower nozzle are suitable for several nozzle changer systems such as Concast (CNM), Danieli (FNC), Interstop (MNC), Krosaki (OTNC), and Vesuvius (CNY/SYS120).

Reviews

There are no reviews yet.