Tundish Nozzle is an isostatically pressed Alumina-Graphite refractory which is intermediate between the Monoblock Stopper and the Sub Entry Shroud. The stopper sits on the Tundish Nozzle to close the flow of steel from tundish to the mould. The tundish nozzle as a part of continuous casting refractories was introduced in order to accommodate hot changing of Sub Entry Shroud for long sequence casting.

Tundish nozzle is an important component designed specifically for continuous casting. It plays a crucial role in the ladle and intermediate ladle, ensuring the smooth progress of the casting process.

Good performance of the nozzle is crucial for steel flow parameters and achieving high tundish sequence, along with clean shut-off of steel flow with the stopper.

Depending on the tundish design, the tundish nozzle can be of different shapes and sizes.

Product Introduction: Tundish Nozzle

Introduction

ATundish Nozzle is a critical component designed specifically for continuous casting applications. It plays a vital role in ladles and tundishes, ensuring the smooth operation of the casting process. Are you aware of the benefits that a Tundish Nozzle can bring to your casting production?

Product Features

- Material: Our Tundish Nozzle is made from high-performance carbon-aluminum composite material, offering excellent heat resistance and oxidation resistance.

- Design and Specifications: We provide a variety of specifications and designs tailored to meet your specific casting system requirements.

- Durability and Performance: Rigorously tested, our Tundish Nozzles can withstand high temperatures and pressures, ensuring stable performance over extended periods.

Application Areas

Tundish Nozzles are widely used in ladles and tundishes, particularly in the continuous casting of steel, where they ensure the smooth flow of metal and help prevent any potential casting defects.

Usage and Maintenance

- Proper Usage Guidelines: Ensure a tight connection with the equipment during installation to prevent leakage.

- Key Maintenance Tips: Regularly inspect the nozzle for wear and replace it as needed.

- How to Extend Product Lifespan? Regular cleaning and maintenance can effectively reduce wear and prolong service life.

Expert Knowledge Sharing

The working principle of a Tundish Nozzle involves its flow channel design, which controls the speed and direction of the metal flow, thereby enhancing casting quality. Factors affecting casting quality include metal temperature, flow rate, and the design of the nozzle itself. Do you have questions about optimizing your casting process? Feel free to learn more!

Common Questions Answered

- What Casting Processes are Tundish Nozzles Suitable For?

Tundish Nozzles are suitable for various casting processes, especially continuous casting. - How to Choose the Right Tundish Nozzle?

When selecting, consider materials, dimensions, and specific process requirements.

Why choose us?

- Wide application and stable quality: Our products have been successfully used in thousands of tundishes, with excellent performance in the global market, stable and reliable quality, and are deeply trusted by international customers.

- Technical support, and customized services: We not only provide standardized products but also customize nozzle size, ingredient formula, and performance optimization solutions according to customer needs to ensure a perfect match with the customer’s production process.

- High-cost performance: By optimizing the production process, we provide more competitive prices to help customers reduce production costs.

Company Advantages

Our company boasts a professional R&D team dedicated to providing high-quality Tundish Nozzles. We also offer excellent after-sales service, ensuring our clients have peace of mind during usage. Additionally, we provide customized solutions designed to meet specific client needs.

Conclusion

Choosing our Tundish Nozzle means opting for a high-performance casting product and a professional, reliable partner. We look forward to advancing the casting industry together with you!

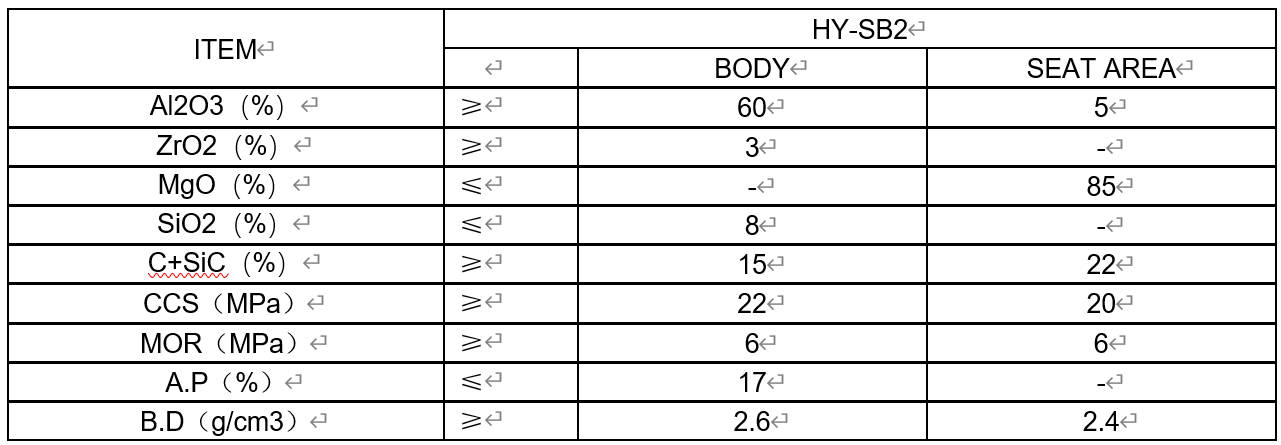

specification of the tundish nozzle

specification of the tundish nozzle

Reviews

There are no reviews yet.