The ladle slide gate system is acritical piece of flow control equipment in liquid steel casting.The service life of the slide gate plate is a limiting factor to achieve performance and is greatly dependent on the type of slide gate mechanism used.A new generation slide gate system is the key to achieving longer plate service life and hence higher productivity and more economical operation.

Introduction

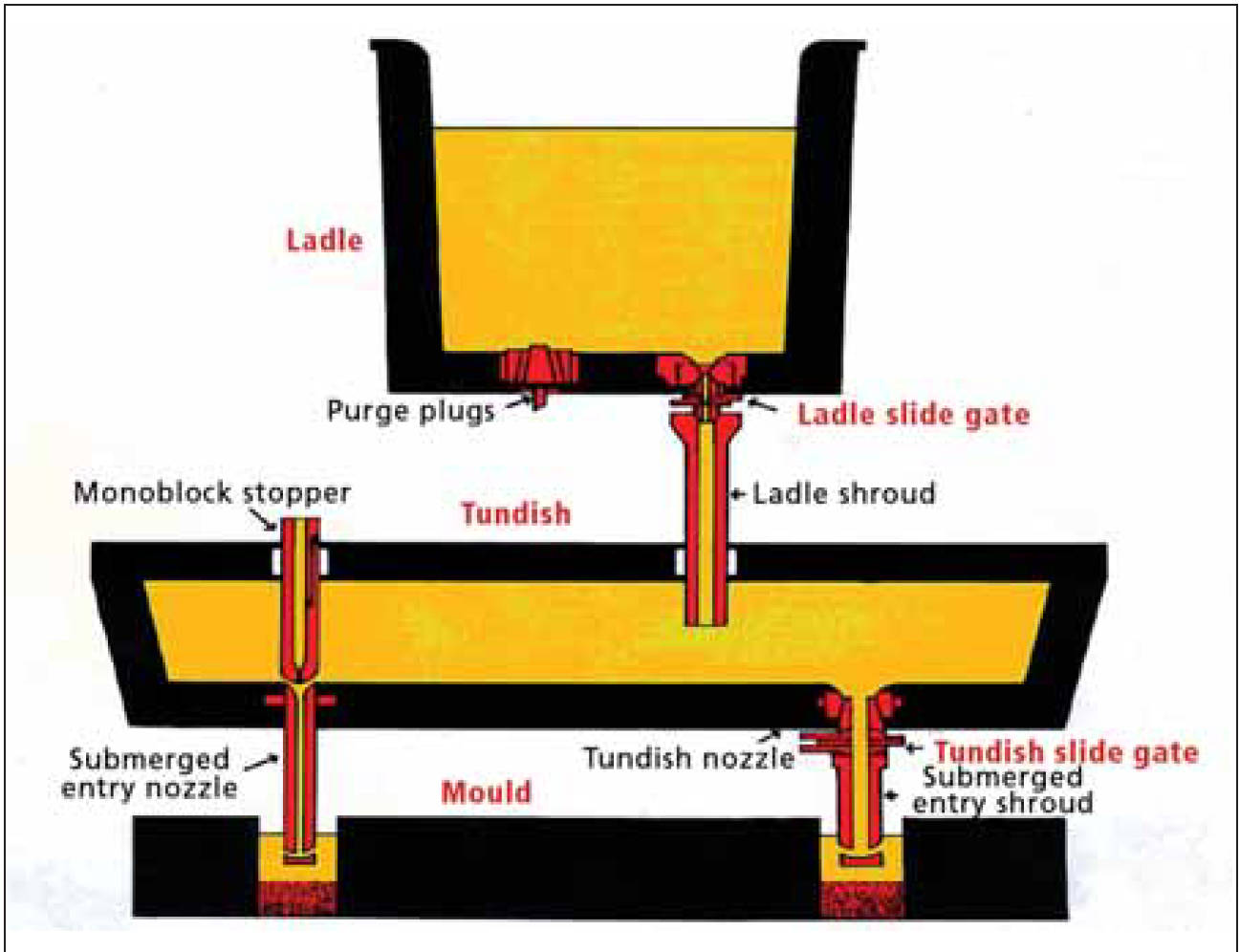

Recent technological advances in steelmaking practices demand longer service life of various supporting process equipment for higher production efficiency and more economical operation. The ladle slide gate system is one of the critical flow control components in the steel casting process. The basic function of the ladle slide gate system is to control the flow of the liquid steel from the ladle to the tundish as shown in figure 1.

For its successful operation it requires a slide gate mechanism and other related refractory components. The slide gate plate is one of the most critical refractory components in the slide gate system for liquid steel casting and metering. It has been observed that the service life of slide gate plates is a limiting factor for improved performance of the slide gate refractory system. Now it has been found that the performance of the slide gate plate is greatly dependent on the type of slide gate mechanism in addition to many other controlling factors such as refractory material, plant operating conditions and steel grades. Therefore a new generation slide gate system is the key to extending the service life of the slide gate plate to achieve higher productivity and economical operation.

Special features of the FF ladle slide gate

The FF series ladle slide gate is a twoplate linear, hydraulically driven gate. The gate valves are designed for small, medium and large capacity ladles. The characteristic features of the FF ladle slide gate are as follows:

– safety and reliability,

– simplicity and robustness,

– higher stroke length,

– automatic face pressure loading,

– outboard spring design,

– optical configuration,

– plate crack control,

– higher face pressure,

lower nitrogen pick-up,

– increased plate life.

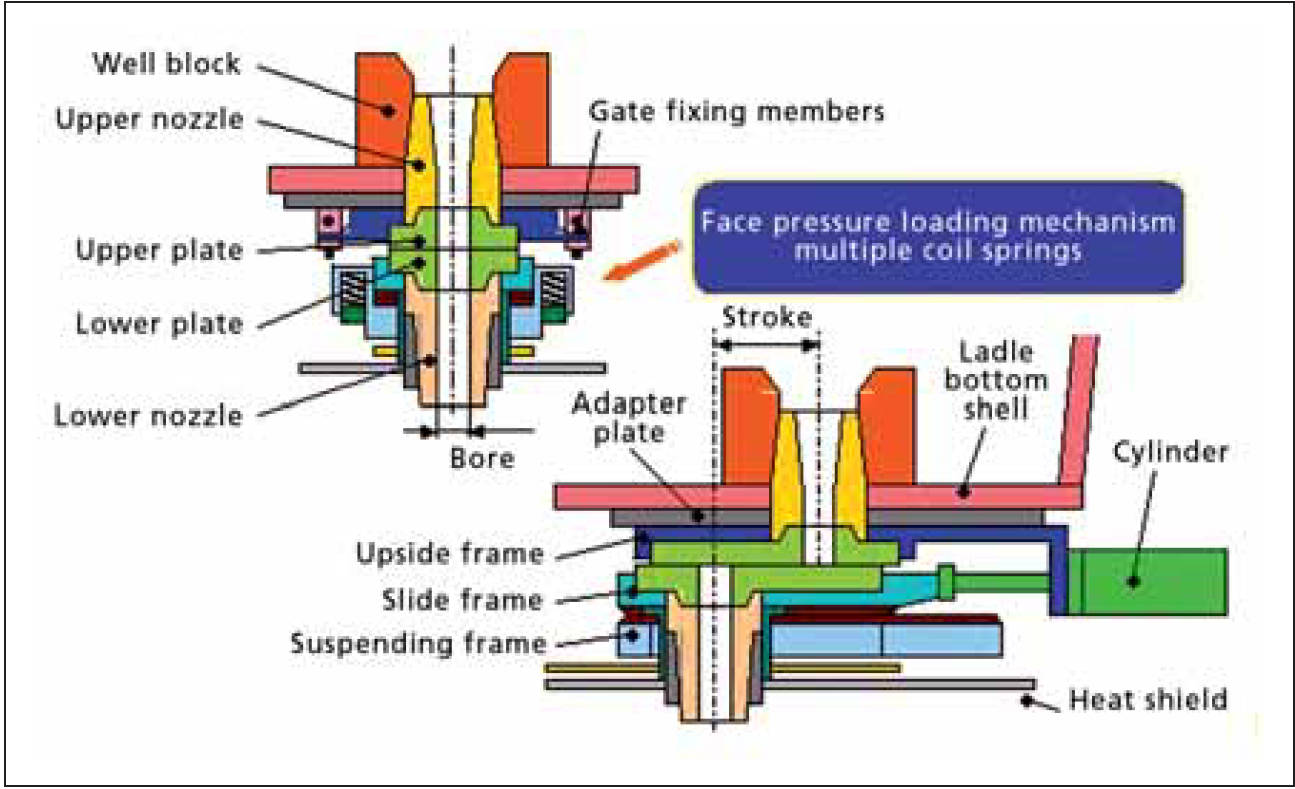

The complete refractory assembly of the FF ladle slide gate is shown in figure 2.

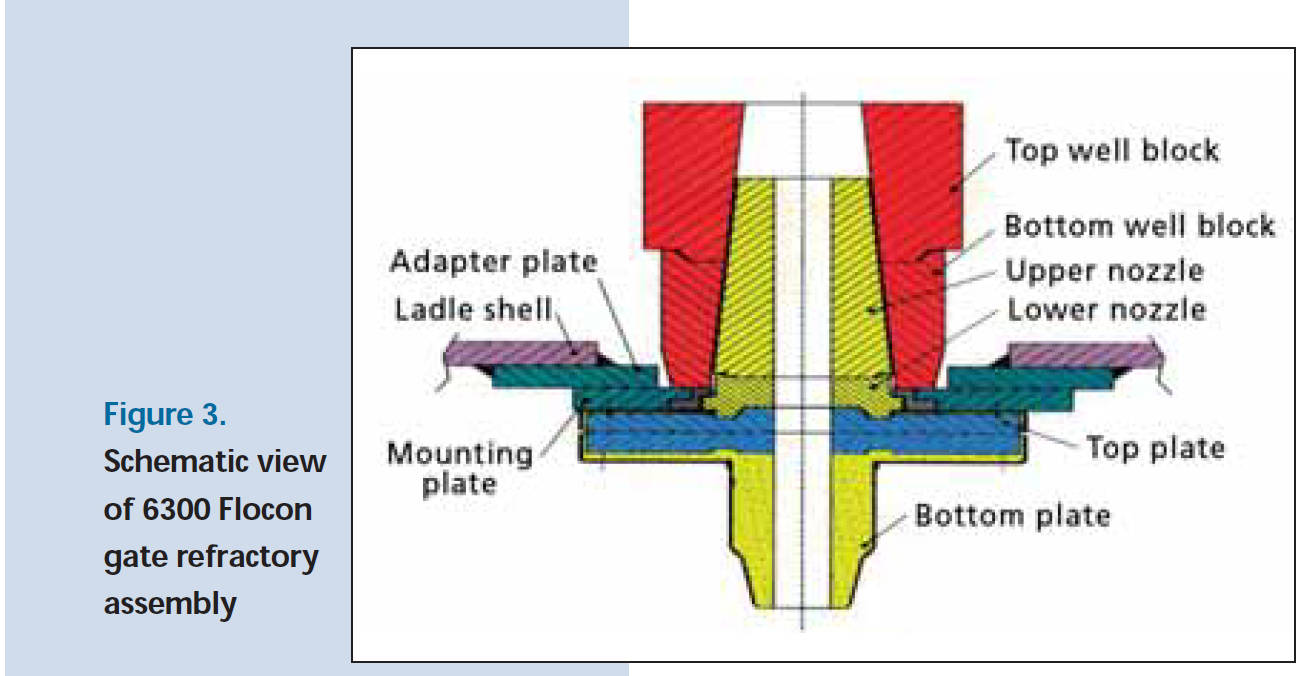

It features a one-piece well block and a one-piece upper nozzle, unlike the conventional Flocon design which uses two-piece well blocks and two-piece ladle nozzles (upper nozzle and lower nozzle), as shown in figure 3.

The fixed and sliding refractory plates are identical in terms of shape and size. The steelencased collector nozzle is detachable and it is available in standard or customized designs. In the Flocon design the top and bottom plates are different and the collector nozzle is built into the bottom plate. The innovative shape is based on 3D stress odelling and finite element analysis studies. Standard steel can has been replaced by hot steel band for crack ontrol.Internal stress distribution has been optimized by the octagonal shape, hot banding and plate clamping, virtually eliminating cracks in the stroke area.The forces act on the plate from four corners resulting in no cracks in the sliding longitudinal direction, which would be very much detrimental for slide gate plate. It has been observed that all cracks are oblique and the stroke area is completely free from cracks. Conventional solutions usually require a good deal of hard manual work to open and close the gate. Due to the automatic face pressure loading of the FF gate, no special tool or any manual effort is required.

Specifications

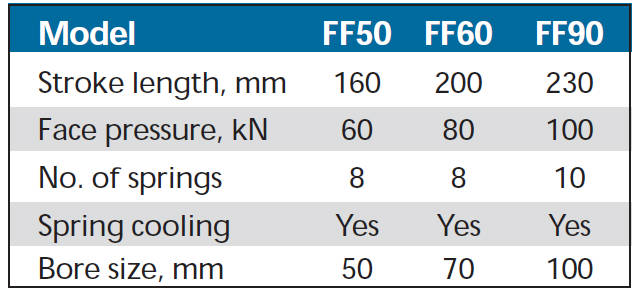

The specifications of the different FF models are shown in table 1.

Here only three basic models are shown for better understanding.However, many other models are available depending on the ladle size and plant operation logistics.The FF ladle slide gate system provides much more safety compared to other gates due to its higher stroke length and other related special features. The FF50 gate which is comparable with the Flocon 4200 gate in terms of bore size has a 46 mm longer stroke length than the Flocon 4200 gate. Similarly the FF60 has a 48 mm longer stroke length than the Flocon 6300 gate. So the additional stroke length provides a higher level of basic operational safety and prolongs the plate life.

Quality improvement in steel and further advantages

Due to the unique pressure distribution in the collector nozzle and the tightness of the mechanism, nitrogen pick-up by steel is minimized. This markedly improves the quality of the steel. It has been observed that nitrogen pick-up has come down dramatically from 60 ppm to 20 ppm after installation of an FF gate. So the FF gate provides an additional advantage over competitor ladle slide gates, which is essential for quality steel making.The new gate provides the following additional advantages:

– faster circulation of ladles,

– lower number of ladles required,

– minimal amount of consumables,

– higher spring life,

– lower inventory due to higher plate life,

– energy savings.

Material selection

The material of the ladle slide gate plate is selected based on many steel plant-related factors and specific perating conditions. Some basic guidelines are given below for general understanding.A specific selection can only be made based on judicious analysis.

Based on steel grade. The basic refractory material of the slide plate must be compatible with the chemistry of cast steel grade. Otherwise, serious problems may occur at any time. The specific selection requires many factors to be taken into consideration.

Based on sliding stroke length. The material of the slide plate is also dependent on the sliding stroke length

of the plate. For smaller plates magnesia-based materials are highly suitable,and for bigger plates alumina-based materials.

Based on caster type. The slide plate material and the proper bonding system are strongly dependent on the caster type. The slide plate is usually subjected to severe throttling and high abrasion in ingot and billet casting.Accordingly, a plate material with a suitable bonding system is to be selected.In slab and bloom casters these effects are much lower. HYRE manufactures the following types of bonding systems for superior plate Performance in any type of casters.

– metal bond – most advanced bonding system with suitable heat treatment,

– lightly burnt metal bond – most advanced bonding system with specifically designed firing,

– carbon bond – most conventional bonding system with proper firing,

– ceramic bond – most stable bonding system with solid state sintering at high temperature.

Based on calcium content in steel.The calcium concentration in the steel plays an important role in the selection of the slide plate material. However, a specific solution can be achieved based on careful consideration and analysis of the operating conditions

Successful field trials

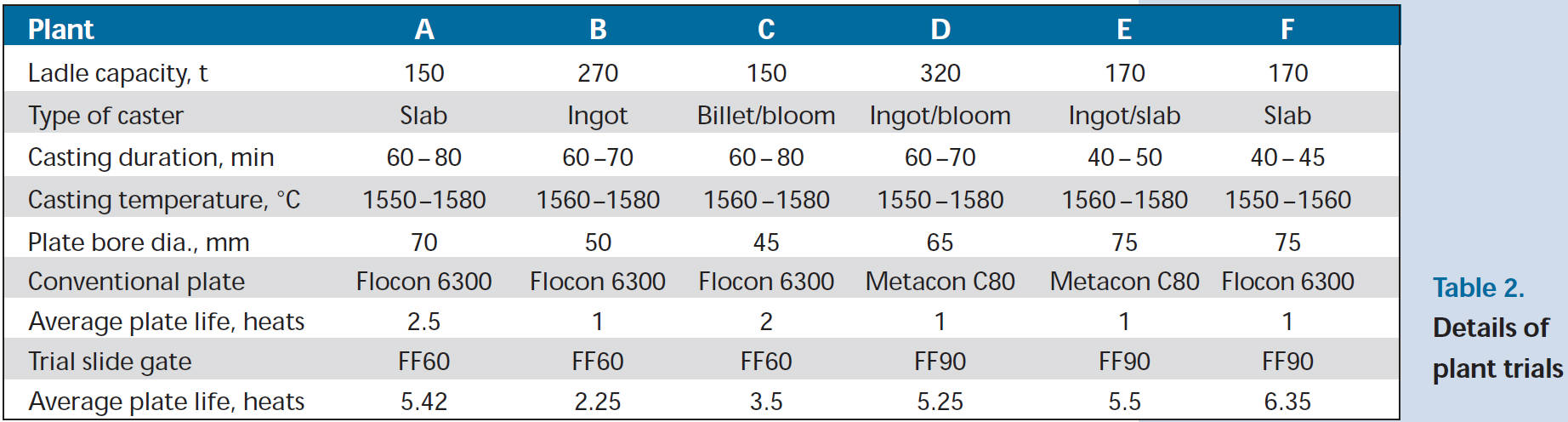

A series of successful field trials have been made in a great number of plants worldwide. The results of six plants.with ladle sizes from 150 to 320 t are summarized in table 2.

FF90 gate was installed in plant D having a ladle capacity of 320 t (figure 4).

Two FF90 gates were working simultaneously in the same ladle for ingot casting. An average plate life of 5.25 heats (maximum plate life of 6 heats) has been achieved – against a plate life of one heat achieved with the existing Metacon C-80 gate.

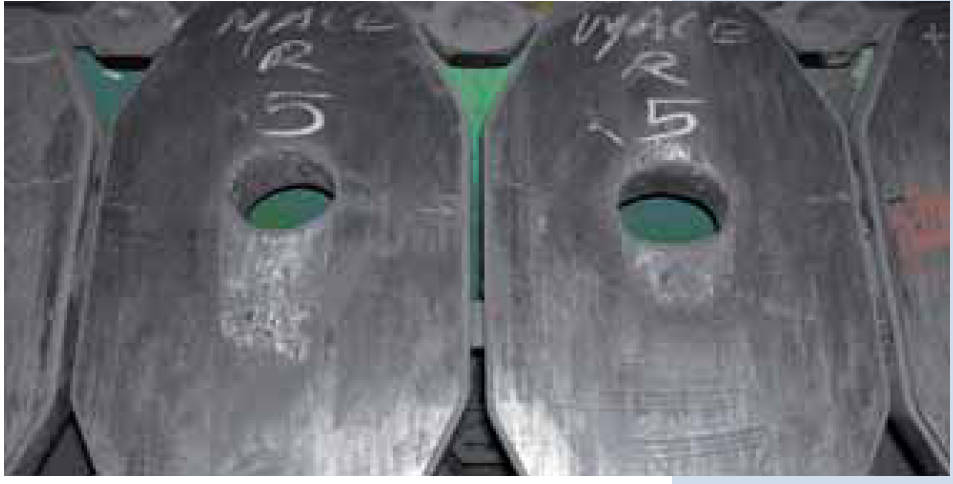

Figure 5 shows the used plate of FF90 after five heats. The plate surface is absolutely clean and smooth. The bore of the plate is also perfectly circular and the edges of bore are very sharp. In general, it was proved that the FF90 plate installed in the FF90 gate performs much better than the existing system.

FF60 gate was installed in plant A having a ladle capacity of 150 t (figure 6).

The casting duration of the single strand slab caster is around 60 minutes.The average plate life achieved was 5.42 heats (with a maximum of 7 heats) against an average life of 2.5 heats achieved with the existing Flocon 6300 gate.

Figure 7 shows the used FF60 plate after six heats. The plate surface is in a very good condition. The bore is circular and the bore edges are in good condition. In general, it was proved that the FF60 plate installed in the FF60 gate performs much better than the existing one in the conventional gate.

Conclusion

From the above series of successful plant trials with the FF90 and FF60 ladle slide gates the following conclusions can be drawn:

The FF slide plate installed in a new generation FF ladle slide gate per forms much better than existing conventional plates.The FF gate definitely supports the process of quality steel making due to less nitrogen pick-up by the steel.The new FF gate provides more oper-ating safety and reliability due to its inherent design.The higher stroke length enables the plate to be used for multiple heats and provides a greater safety margin.Multiple heats make the system more economical. Finally the new generation FF ladle slide gate is the key to achieving improved slide plate performance.A detailed analysis of the field results provides a comparison of the perform-ance of the slide gate plate used in the new generation FF slide gate system with conventional Flocon and other systems. It was found that the service life of the slide plate has increased many times in various steel plants, with the FF mechanism being of the same refractory material. This new sys-tem ensures higher safety and reliabili-ty along with higher service life.