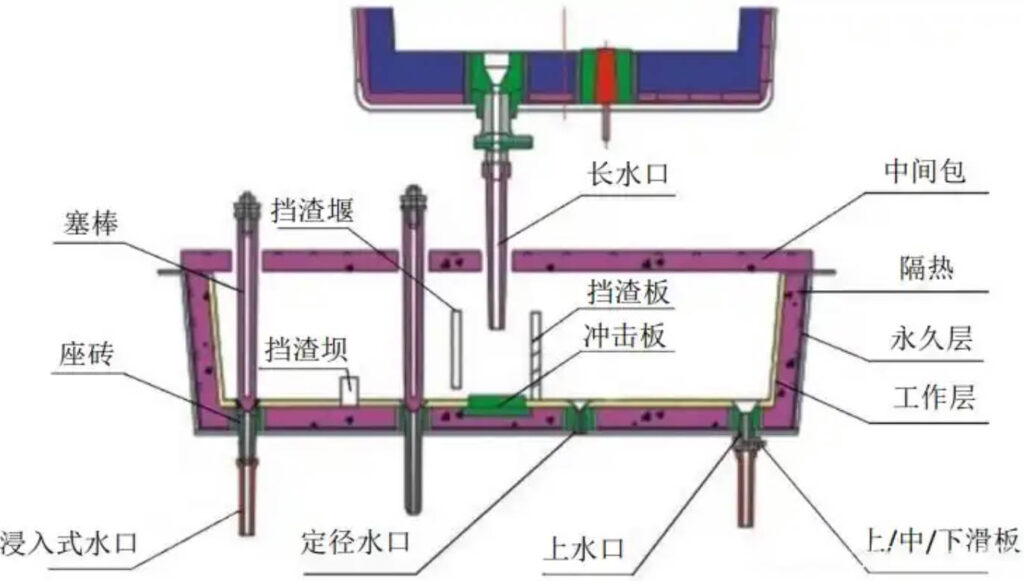

The tundish, serving as a transitional device between the ladle and the casting mould in continuous casting, is not only a storage and distributor of molten steel but also a refining vessel. It stabilizes the steel flow, reduces the scouring of the billet shell in the casting mould, and ensures a reasonable flow field and appropriate residence time for the molten steel within the tundish. This guarantees uniform steel temperature and the separation and flotation of non-metallic impurities, ensuring steel cleanliness and enabling multi-heat casting. It is a crucial link in improving steel quality and continuous casting efficiency. Its structure is shown in Figure 1.

The main tasks of the tundish are:

(1) Distributing molten steel. For multi-heat continuous casting machines, the tundish distributes molten steel to each casting mould.

(2) Stabilizing flow. Reducing the static pressure of the molten steel, maintaining a stable liquid level in the tundish, and smoothly injecting molten steel into the crystallizer.

(3) Storing molten steel. Maintaining the casting speed during ladle changes in multi-heat casting, creating conditions for multi-heat casting.

(4) Purifying molten steel. During a prolonged pouring time, the molten steel temperature remains essentially constant, promoting the further floating of inclusions and preventing contact between the molten steel and air, thus avoiding oxygen and nitrogen absorption.

Refractory materials for tundishes can be functionally classified into three categories:

The first category is lining materials, mainly composed of an insulation layer, a permanent layer, and a working layer.

The second category is flow stabilizing components, including slag skimmer block, slag impack board, and impact pot;

The third category is flow control components, including tundish stoppers, sliding gate plate, tundish metering nozzles, and submerged entry shroud . For small billet continuous casting, the core of efficient continuous casting is high casting speed. This requires maximizing the continuous operation rate of the continuous casting machine and the pouring speed, while ensuring the molten steel quality meets requirements, to achieve high billet exit temperature and billet quality. These technical indicators place two demands on tundish refractories: high performance and long service life.

tundish metering nozzle

tundish metering nozzle

The refractory lining of the tundish generally consists of the following parts:

(1) Insulation layer (10-30mm):

This layer is adjacent to the steel shell of the tundish and is usually made of asbestos board, insulating bricks, or lightweight castable. Alumina silicate fiber felt is the most effective due to its low thermal conductivity and ease of installation.

(2) Permanent layer (100-200mm):

This layer is in contact with the insulation layer and is generally made of clay bricks. Integral permanent lining is the most common, and the castable is usually high-alumina or mullite self-flowing castable.

(3) Working layer (20-50mm):

This layer is in contact with the molten steel and is a critical part. Insulation boards or coatings are now commonly used. Insulation boards are generally made of silica, magnesia, or forsterite; coatings are made of magnesia, magnesia-chromium, or magnesia-calcium. Coatings are applied by mechanical spraying or manual application.

(4) Seating blocks:

These are embedded in the bottom of the tundish for installing the tundish nozzles and are usually made of high-alumina material.

(5) Tundish Bottom:

Its material is basically the same as the working layer. The working layer of the tundish bottom is easily damaged by the impact of molten steel, requiring corrosion resistance and wear resistance. High-alumina bricks, dense high-alumina bricks, and alumina-chrome bricks are generally used, as well as specially made large high-strength tar-magnesia bricks. Zircon bricks or precast blocks are used to reinforce the impact areas.

(6) Tundish Cover:

Covering the tundish, it serves to insulate against molten steel splashing. It is made of clay or high-alumina castable refractory.

(7) Slag skimmer block:

This wall is built inside the tundish and can be a single wall or a double wall. The slag retaining wall/weir is usually made of high-alumina bricks, but can also be made into precast blocks. Its purpose is to retain molten steel. To improve the cleanliness of the molten steel, a molten steel filter can also be installed on the slag skimmer block.