Monoblock stoppers rod play a very important role in continuous casting ( short for CC) . Sometimes the stop per slag line is seriously eroded and broken CC has to pause. The research shows that there are three main rea sons which bring severe erosion of monolithic stopper slag line. Firstly much Fe2O3 and MnO in slag react with carbon ( C) in the stopper C is gradually eroded and erosion resistance of the stopper greatly weakens.Secondly F increase in tundish covering flux will quicken ero sion of the stopper slag line. Thirdly High LOI of tundish covering flux also makes erosion of the stopper slag line speed up. On one hand CaCO3 in tundish cov ering flux decomposes and brings CO2 ; on the other hand minerals with water in tundish covering flux de compose at high temperatures and bring water vapor.Then CO2 and water vapor react with C in the stopper C is gradually eroded aggravating the erosion.

Key words: monoblock stopper; slag line; severe erosion; slag; tundish covering flux

1.Preface

CC functional refractories for flow control systems play a very important role in exact flow control of mol ten steel and improvement of the qualities of molten steel and casting billet. There are three continuous casting machines ( CCM ) which have stopper flow control systems in Baosteel. But serious erosion and break had happened several times which paused CC and gave rise to a bad influence on normal CC produc tion.What are the reasons of the serious erosion and break of stopper slag line? The special investigation and research were carried out on various possible rea sons and the clear conclusions were gotten in this paper.

2.Severe Erosion of stopper slagline

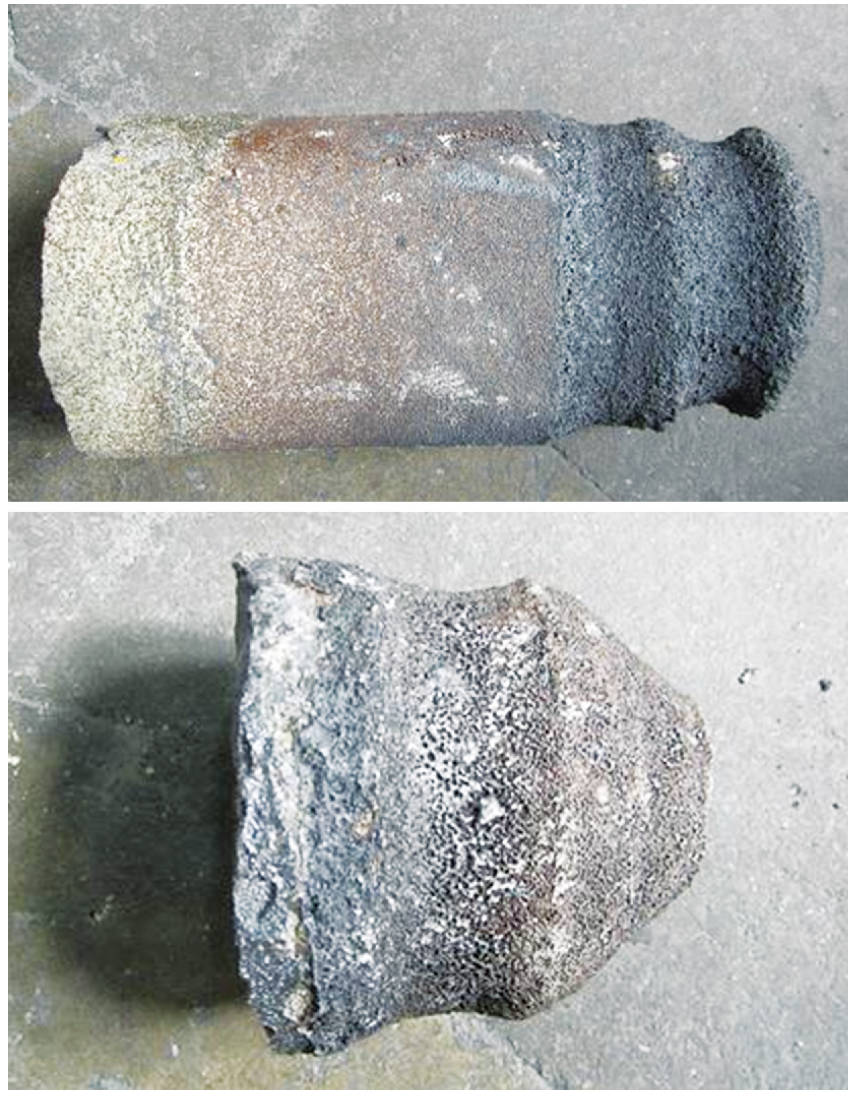

The stopper slag lines were researched during 2014 - 2015. In Feb,2014 the 1st stopper slag line in 5#CCM was seriously eroded CC had to pause; the 2nd stopper slag line was eroded normally.In July 2014 when 5#CCM was casting the forth heat two stoppers were broken one after another ( see Fig. 1) ,CC had to pause.

In Sept. 2014 when 5# CCM was casting the second heat the 1st stopper slag line was broken ( see Fig. 2) ;

the 2nd stopper slag line was seriously eroded but it was not broken.

On July 2 2015 when 5# CCM was casting the fifth heat the 1st stopper slag line was broken ( see Fig. 3) ,and the 2nd stopper was normal.

On July 3 2015 when 1# CCM was casting the first heat two stoppers were broken one after another ( see Fig. 4) .On July 6 2015 when 1# CCM was casting the second heat two stoppers were both.

On Sept,2 2015 after 5# CCM had cast 3 heats of high-oxygen steel two stoppers were both broken as shown in Fig.5

3.the analysis on chemical composition of slag adhered to residual stopper.

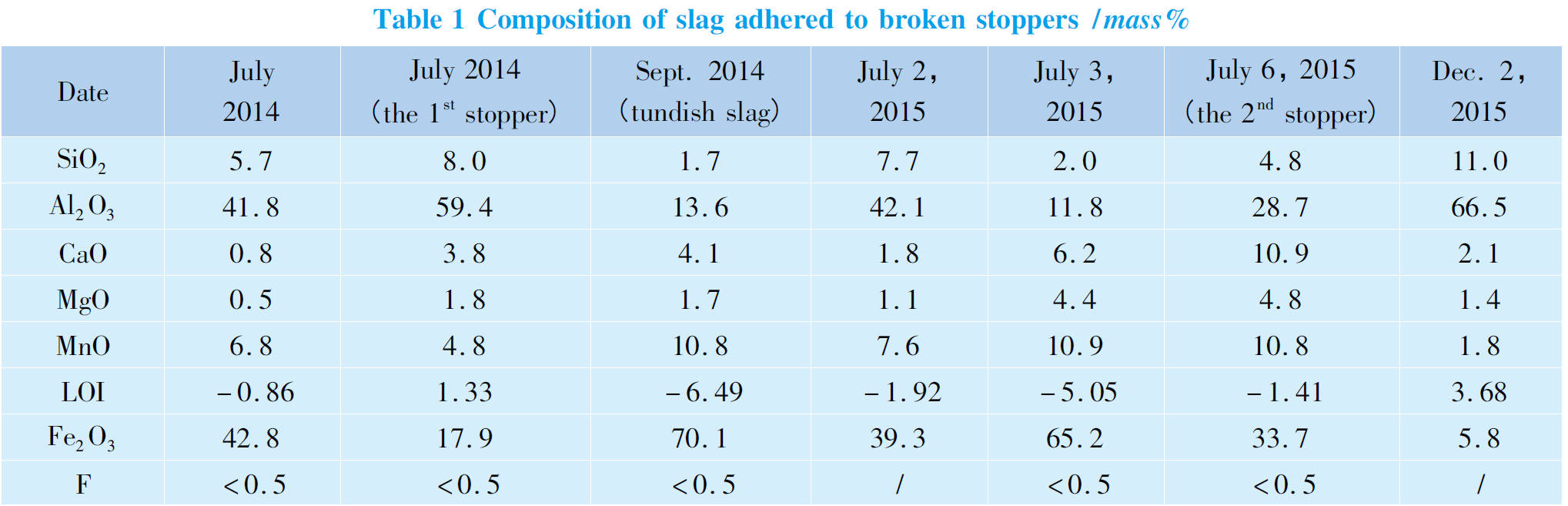

The chemical composition of the slag adhered to broken stoppers and tundish slag was analyzed and the results are listed in Table 1. Except the last one the slags have abnormally high contents of Fe2O3 and MnO. Possibly the molten steel in tundish has been partially oxidized and slag from the steel ladle came down into tundish.

By analyzing the tundish covering flux ( see Table 2) , it was found the F content of the covering flux was high er than the standard ( < 1. 5% ) . For the stopper acci dents happened in Feb. 2014 and on July 2 2015 the 2nd stopper was normal confirming that the F con tent of covering flux was not higher than the standard

4.the analysis on severe erosion of stopper slagline

4.1 Influence of Slag Composition

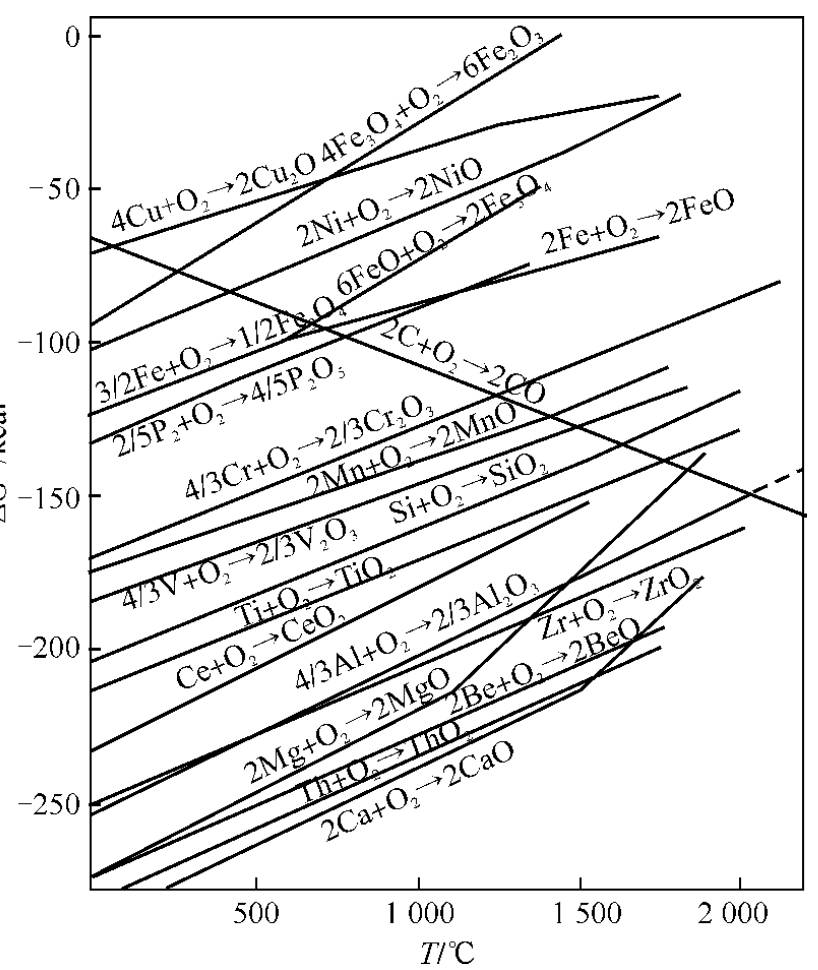

Fe2O3 and MnO in slag have strong erosion to car bon-containing refractories because Fe2O3 and MnO can react with C at lower temperatures. According to the relation between standard formation free energy of oxides and temperature ( see Fig. 6 )

the reaction temperature of Fe2O3 and C is under 1 000 ℃ . Ferric oxides are in different forms. For the reactions of Fe2O3 and C Fe2O3 first transforms into Fe3O4 then Fe3O4 transforms into FeO at last FeO transforms into Fe. The reactions are as follows

3Fe2O3 + C ====2Fe3O4 + CO ( 1)

Fe3O4 + C === 3FeO + CO ( 2)

FeO + C ===Fe + CO ( 3)

Reaction ( 1) begins at about 250 ℃ reaction ( 2) at about 700 ℃ and reaction ( 3) at about 750 ℃. MnO existing in the slag reacts with C according to reaction ( 4) . It begins at about 1 420 ℃ . MnO + C === Mn + CO ( 4) In this way much Fe2O3 and MnO in the slag re act with C in Al2O3 - C stopper during CC. C is gradu ally eroded and the erosion resistance of the stopper slag line is greatly weakened.

4.2Influence of F Content in Tundish Covering Flux

F in the tundish covering flux has strong erosion to refractories. The higher the F content is, the stronger the erosion is.

Tables 1 and 2 show that on Dec,2 ,2015 the contents of Fe2O3 and MnO in adhering slag of the bro ken stoppers are not high and the F content of the covering flux is not higher than the standard. But to people’s surprise LOI of the covering flux arrives as high as 20. 7% . It is because that the main compo nents in the covering flux are CaO and Al2O3 some CaO is from CaCO3 . During CC CaCO3 decomposes into CaO and CO2 at about 900 ℃ and brings about a great amount of CO2 .

CO2 reacts with C in the stopper forming CO above 1 000 ℃ C is gradually eroded and the erosion resistance of the stopper is greatly weakened.

4.3Influence of LOI of Tundish Covering Flux

On the other hand some water is added to granu late during the production of the covering flux. Water reacts with the covering flux and forms Ca( OH) 2 and Mg( OH) 2 which decompose at high temperatures and bring about water vapor according to reactions ( 5) and ( 6) ,which reacts with C in the stopper and forms wa ter gas according to reactions ( 7) and ( 8) . Ca( OH) 2 → CaO + H2O ( 5) Mg( OH) 2 → MgO + H2O ( 6) H2O( g) + C → CO + H2 ( 7) 2H2O( g) + C → CO2 + 2H2 ( 8) Reaction ( 5) begins at about 580 ℃ and reaction ( 6) begins at about 350 ℃ .

Therefore the reason of the last abnormal erosion of the stopper is that CO2 and H2O vapor from high LOI covering flux react with C in the stopper which weak ens the erosion resistance of the stopper.

5.conclusion

( 1) There are three main reasons for severe ero sion of monolithic stopper slag line. First much Fe2O3 and MnO in the slag react with C in the stopper C is gradually eroded and the erosion resistance of the stop per is greatly weakened. Second F increase in the tundish covering flux will quicken the erosion of the stopper slag line.The last high LOI of tundish covering flux also speeds up the erosion of the stopper slagline.

( 2) Effective measures have to be taken to de crease abnormal erosion of the stopper slag line: pre vent molten steel from the secondary oxidation control Fe2O3 and MnO contents in slag and reduce F and LOI in tundish covering flux.