Continuous casting refractories are the most important materials that provide critical flow control components in steel making process. Ladle slide plates, named in this group, are subjected to sudden thermal shock, physical erosion of molten hot metal and slag. Therefore, the slide gate plate must have good resistance to both thermal shock and corrosion. Generally, alumina based plates are used for Al-killed steel casting processing, however these plates are subjected to huge corrosion during alloy casting which contains higher amount of Mn, Cr or Ca (Ca >15-30ppm) . In order to overcome this major concern ZrO2 additives have been started to be used. Its well-known that, addition of Ca is the best way to avoid Al clogging problems in Al killed steels. However, the Ca content in Al2O3-ZrO2-C (AZC) slide plates results in increased corrosion. Hence, it is necessary to determine the most suitable ZrO2 percentage content in the sliding plate for the continuity of the process and the reliability of continuous casting.

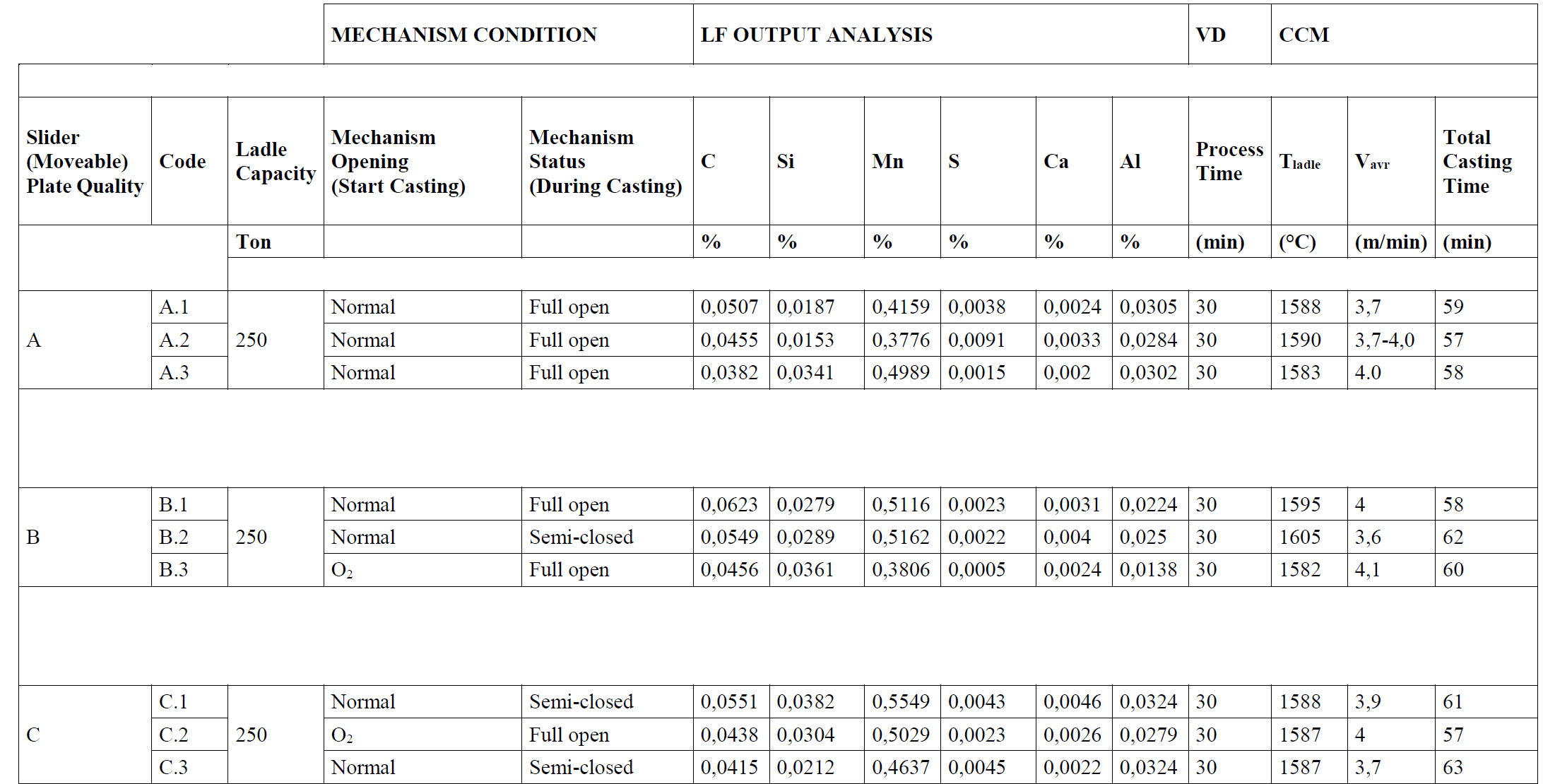

The present paper deals with corrosion and diameter expansion comparison results of three different content of ZrO2 slide plates that used in 250-ton ladles in medium carbon Al-killed steel production. In the comparison studies, LF (Ladle Furnace) output analyzes, temperature of liquid steel (Ts-liq -s), casting speeds, total casting times values and operating factors such as full open or semi open operation of the mechanism were taken into considered.

The test results provide information about which zircon ratio is suitable for a reliable casting process and the maximum number of castings that can be achieved.

Keywords: Al2O3-ZrO2-C; Slide gate plates; Casting

1. Introduction

In the production of clean steel, as in many refractory products, continuous casting refractories are asked to meet the expectation have long-life, economical and safe flow control. Ladle slide plates which are the one of the continuous casting refractories, are materials that provide controlled steel flow from the ladle to the tundish. Therefore, the temperature strength properties of the refractories used for ladle slide plates should be given more importance since they are in first contact with hot liquid steel

Together with the advancing technology, different steel qualities and increased capacity, the ladle slide plate contents have started to vary due to its great impact on steelmaking cost. Operating conditions (capacity, time, cost) in terms of refractory requirements for ladle slide plates are listed as follows:

a) High thermal shock resistance

b) Erosion resistance to metal slag

c) Low coefficient of thermal expansion

d) High thermal conductivity

e) Good crushing strength

f) Abrasion resistance

In general, the refractory raw materials used in the sliding plate are high Al2O3 and MgO based materials. The addition of carbon brings in high thermal conductivity, low coefficient of thermal expansion and non-wettable properties to Al2O3-C. Additionally, it also has some advantages such as high resistance to thermal spalling, to abrasion, to erosion and corrosion. It minimizes the contact between the slag and refractory [3]. However, as with all refractory materials, some factors affect corrosion in continuous casting plates. There have been many studies investigating the corrosion of carbon-bonded Al2O3 materials in continuous castings.

Some studies conducted for corrosion related cracks in plates, laboratory and operational trials have been carried out by focusing on tabular alumina ratio.

Furthermore, the problem of Al clogging in Al-killed steel production is a common problem which affects not only the slide plates but also the tundish continuous casting refractories and causes the casting to stop. The addition of Ca to the steel is effective way for preventing Al clogging problems in Al killed steels because Ca reacts with alumina inclusions and forms low melting point calcium aluminates, which do not form precipitated layers. In general, Ca treatment range is between 15-30 ppm in Al-killed steel production. However, it is known that the corrosion of Al2O3-ZrO2-C (AZC) slide gate plates increases when they are used for the casting of Ca-added steel.

Therefore, ZrO2, which has high corrosion and erosion resistance, has started to be used. Some studies focus the subject of “ceramic / steel / slag local corrosion attack” has been investigated with different ZrO2 forms and different grain sizes.

For improving corrosion resistance and hot strength, ZrO2 is added to Al2O3-C refractories. In order to obtain different properties, like to improve toughness and mechanical strength, different additives are added, like silica and micro silica, in combination [10]. Similarly, in an another comparison study with a standard Al2O3-C plate and ZrO2 plate, it was evaluated that steel samples inclusive CA6 aggregate (which formed due to Ca treatment) penetrated into the standard Al2O3-C slide plate matrix. It was also found that ZrO2 containing plate was 30% better in terms of corrosion resistance. However, a comparison with a sample containing only 20 ppm Ca content and 13% ZrO2 does not give an idea about the optimum ZrO2 ratio.

In another study related to the subject, the interaction of Al2O3-ZrO2-C and Ca was investigated in the samples of three different slide plates. However, calcium interaction was studied only under laboratory conditions. As mentioned in the study, the effects of process parameters such as Ca ppm, casting speed, oxygen opening should also be taken into consideration, which will be the case in this study.

In this study, corrosion and bore diameter changes of sliding plates containing ZrO2 in different ratios were observed. The maximum number of castings was determined with these refractories. All experiments and observations were performed under controlled casting conditions and in real-time production conditions.

2. Operational Procedure

a. Properties of Materials

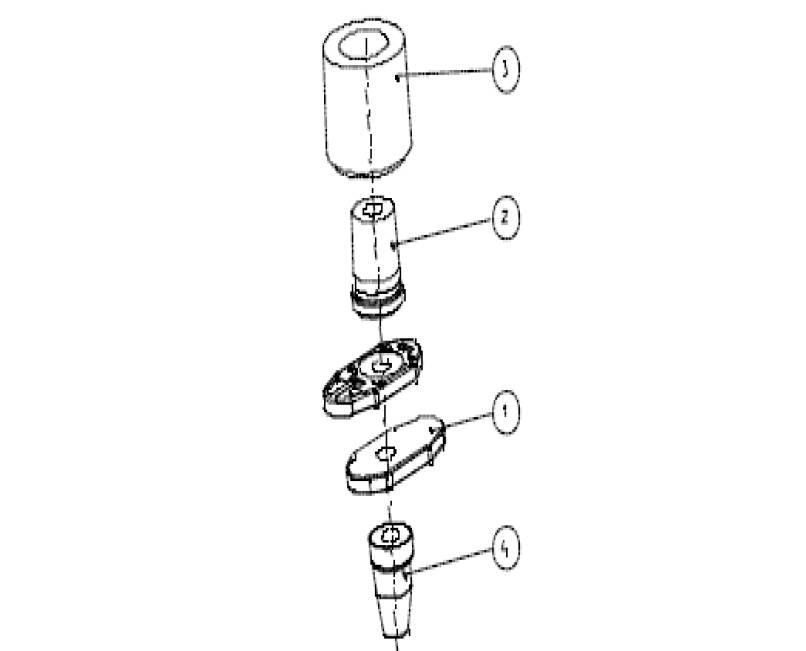

Deciding on the type of plate refractory depends on the characteristics of alloying materials in the steel, residual impurities, ladle capacity and even the tundish filling speed and cast speed. Hence, a good understanding of the process and knowing the reasons for the degradation of the plate gives the necessary information for process improvement. In some cases, producers aim to choose to maximize the amount of steel produced per each cast. Therefore, the establishment of an automatic sliding gate control system aided by slag detection sensors is preferred by the manufactures. Figure 1 shows the slide gates plate’s refractories mounted in the slide gate mechanism as a pair and Figure 2 shows the general refractory layout.

(1: Side gate plates, 2: Inner nozzle, 3: Ladle well block, 4: Outer nozzle-exchangeable)

Most of the refractory requirements for slide plates, which are mentioned above, are satisfied by Al2O3-C refractories. The presence of carbon gives them good resistance to abrasion, corrosion and thermal spalling. Carbon has non-wettability property, which prevents the infiltration of metal and slag to the system. In addition, carbon will improve the thermal shock resistance of the material. Al2O3-C refractories are having good flexural and compressive strength at high temperature, which prevents erosion by molten steel and slag. Apart from these properties, Al2O3-C has high thermal conductivity and low coefficient of thermal expansion resulting in high resistance to thermal spalling. Good affordability assisted by above mentioned properties make Al2O3-C a potential candidate flow control refractories in Iron and steel industries.

The technical characteristics of the three samples (coded as A, B, C) with different ZrO2 ratios used in the study are given in Table 1.

Apparent porosity and density test results obtained according to ASTM C 20-00. Leco SC-144 DR Carbon / Sulfur Analyzer was used for carbon analyzes and Thermo ICAP 7400 ICP-OES was used for oxide analysis. The materials of all the examples are carbon impregnated. Samples A and B are carbon bonded and sample C is ceramic bonded refractories. Carbon bond is most conventional bonding system with proper firing; ceramic bond – most stable bonding system with solid state sintering at high temperature. In the chemical analyzes, the analysis of these regions called inserts were taken separately and only the ZrO2 ratio was examined. As shown in the table, the ZrO2 ratios of samples A and B are relatively close to each other; in general, it is known that the ratios of ZrO2 in the sliding plates used on the market are such.

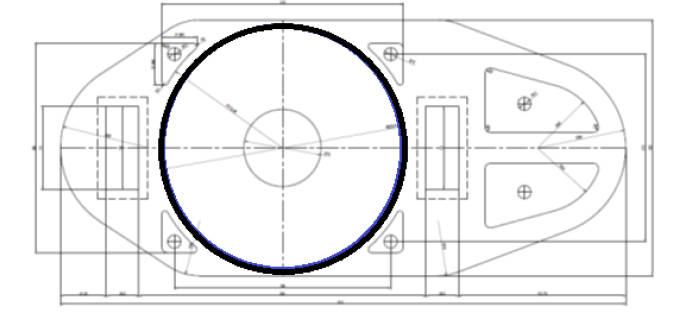

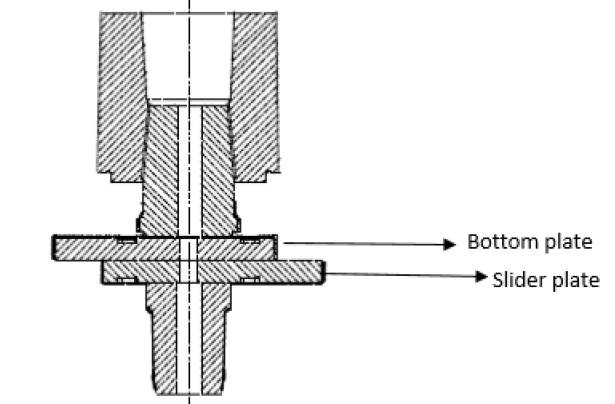

The plate diameters used in the experiments were selected by calculating 70 mm according to casting parameters. The area shown in bold in Figure 3 is the portion forming the plate casting zone (insert). Figure 4 shows the mounting process of slide plates.

b. Operational Conditions (Experimental Methods)

A total of 9 plates were tested in three different quality plates such as A.1, A.2, A.3. In order to better observation of the condition of the plates and to ensure casting safety, testing slide plates was used in only one of the ladles.

Another situation subject to observation is the mechanical stress that occurs due to the fully open or semi-closed mode of the mechanism during casting. Depending on the filling speed of the tundish or in cases where the casting speed needs to be reduced, the mechanism is operated at semi-closed. This naturally leads to an increase in ferrostatic pressure on the insert surface. Examinations after casting, the results were obtained according to the measurements (number of casting and diameter change) taken from slider plates due to it was subjected to friction movements and more mechanical stress.

In Figure 5 shows some plates coming out of casting.

The casting data and mechanism operating conditions of 9 plates of 3 grades are given in Table 2.

3. Result and Discussion:

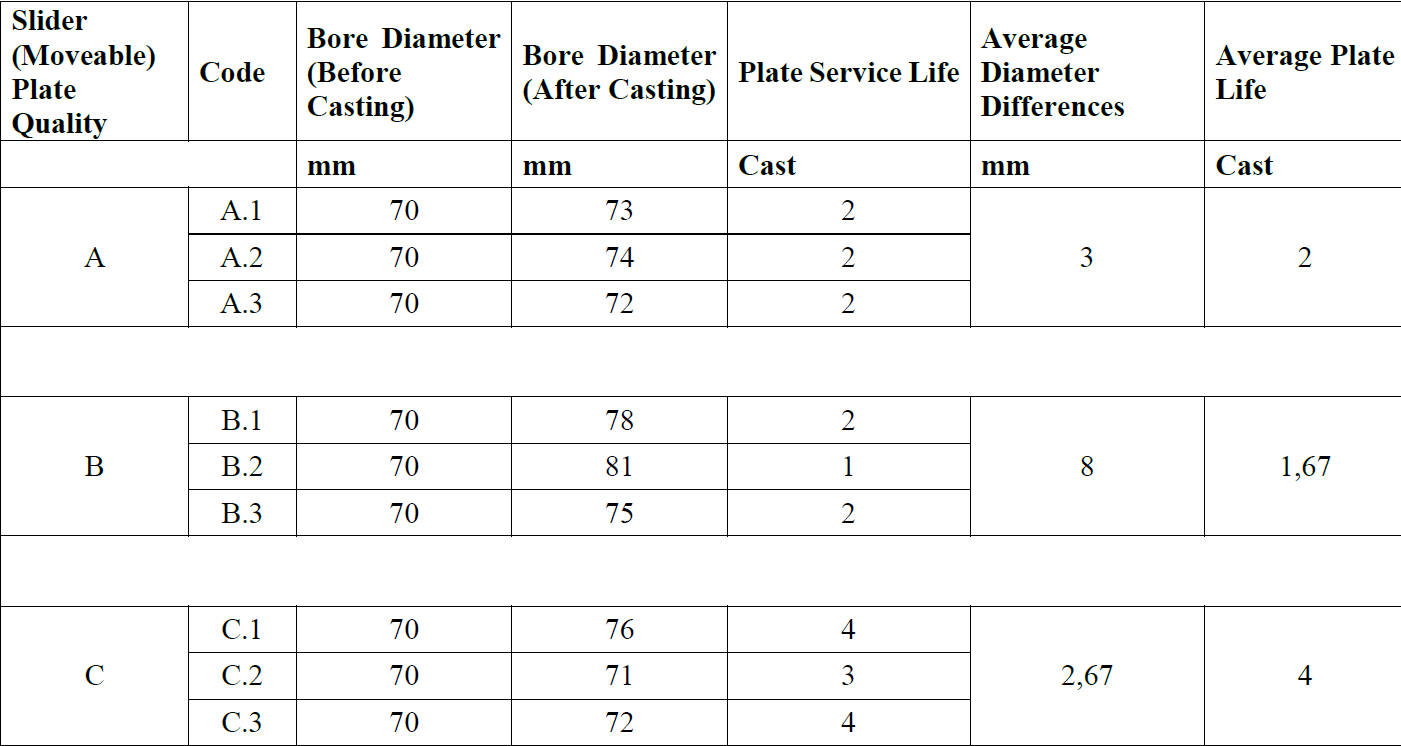

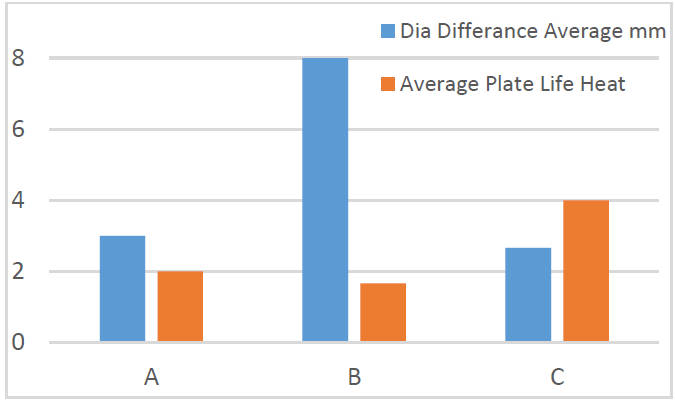

By examining the working conditions of the plates coming out of the casting, the diameter changes and the number of castings taken are given in the Table 3.

By examining the results, plates with high ZrO2 (C coded tests) even high Ca ratios in steel (23 ppm-46 ppm), diameter expansion is within acceptable limits in case of opening with O2 and semi-closed operation. Additionally, by examining the surface structure of the plate, macro cracking or steel/slag penetration was not observed. The casting conditions in the A coded test products is also acceptable and provide safe casting conditions with 3 mm bore diameter change and castings two times. No steel leakage was observed between the plate. In the B coded product, especially after high Ca treatment and during casting, it was observed that due to the semi-closed working condition, the steel was leakaged between the plate and a serious corrosion occurred in the surface area. It is concluded that the 5% ZrO2 ratio is not sufficient for the insert region (high Ca ratio), and semi-closed operating conditions.

As shown in Figure 6, there is no extreme differences between casting speeds. Although the casting time of B and C samples are close, it appears that C sample receives significantly more castings.

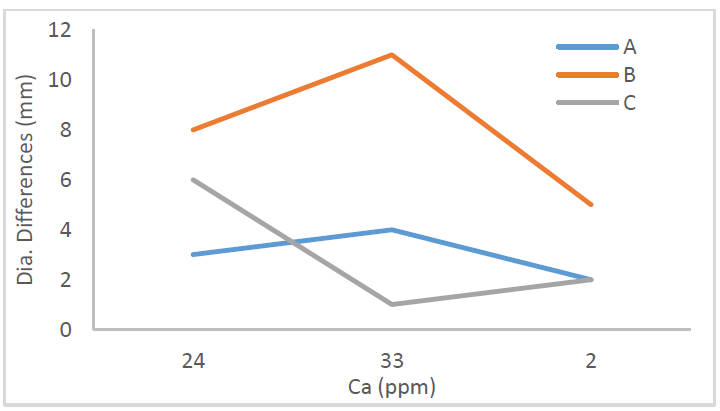

Diameter difference after Ca treatment is shown in Figure 7. As can be seen from the Figure 7, the A and C test materials seem to be acceptable as mentioned above. It can be said that even 5% ZrO2 ratio is insufficient in the penetration of calcium aluminate due to Ca which is sometimes used in the upper limits under variable operating conditions. 5% ZrO2 ratio can only be accepted as lower limit for operating conditions.

Figure 8 shows the correlation between CCM parameters and plate life. As it can be observed from

the Figure 8 that C type refractory test material show showing the best results compared to the others based on the casting time, Vavr., and average plate life values.

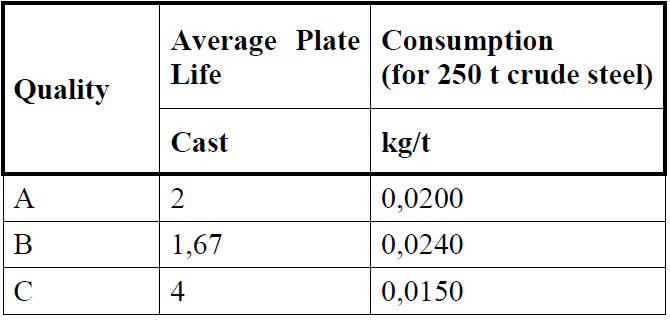

The plate consumption calculation is performed for 250 tons crude steel (1 ladle) based on the average number of castings taken. It is observed that C and A plates are more suitable because of lower consumption rate than B (Table 4).

4. Conclusion

In this study, corrosion resistance of the different ZrO2 content slide gate plates used in production under real-time process conditions were investigated. Slide gate plates refractories are corroded related to too many factors such as raw materials used in manufacture, casting speed, opening with O2, steel grade, mechanism working conditions. Experiments were evaluated by considering variables such as LF output analysis, casting rate, casting times, mechanism working conditions and Ca processing rates.

Experiments clearly show that the minimum ZrO2 ratio to be used in cases where high Ca treatment is required is 5%, depending on operating conditions. However, high Ca ratio should not be considered as the only factor. The mechanism of semi-closed working conditions and the slide plate opening procedure with O2 are other factors affecting the corrosion of the material. According to these results, if the Ca treatment range is kept between 15-30 ppm and suitable CCM conditions are available, it is possible to continue casting with a class A plate. However, since it is known that slider (moving) plates are subjected to more mechanical stress, it is recommended that class B plates be used only as fixed (bottom) plates. Type C plates are suitable for both casting safety and the desired controlled flow when working with high Ca ratio applications or under difficult conditions (new casting trials, first casting trials, etc. or where CCM parameters change when high casting quantities are targeted).

In continuous casting, it is important to ensure controlled flow, but it is always necessary to examine refractory applications in terms of cost.

The consumption calculation is performed for 250 tons crude steel (1 ladle) based on the average number of castings taken. It is observed that C and A plates are more suitable because of lower consumption rate than B.