Currently, representative quick-change mechanism of tundish metering nozzle at home and abroad include:

(1) Concast nozzle adjustment mechanism (CNM);

(2) Danieli nozzle replacement mechanism (FNC);

(3) Interstop metering nozzle replacement mechanism (MNC);

(4) Kurosaki Industries online tundish nozzle replacement mechanism (OTNC);

(5) Vesuvius calibration nozzle replacement mechanism (CNC).

Although there are many quick-change systems, they can be summarized into two main methods in terms of replacement: 2. Quick replacement methods include:

1.Hydraulic quick change method:

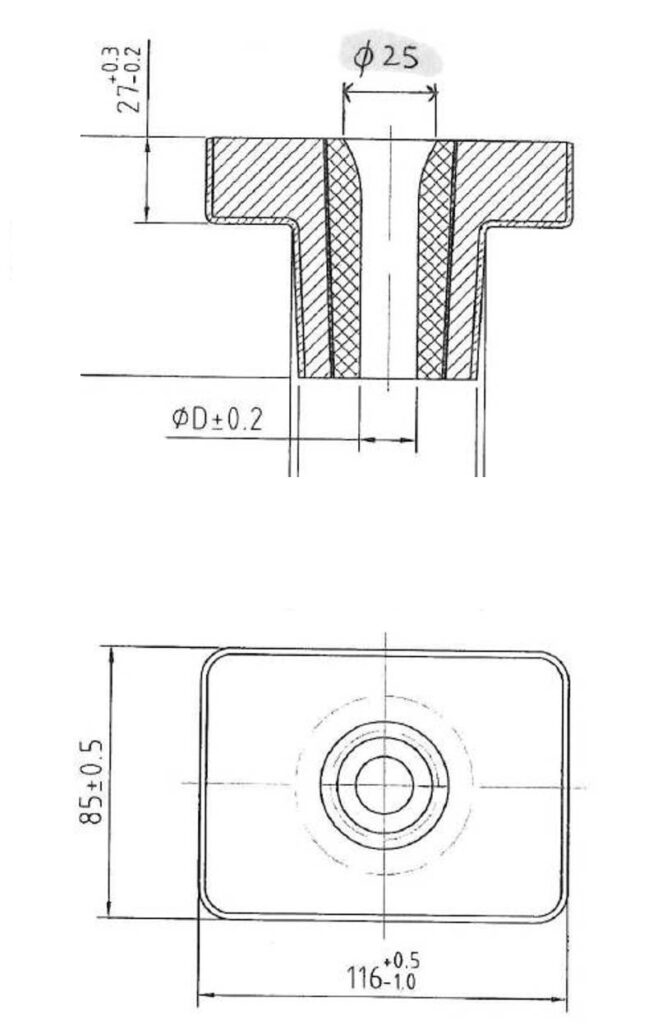

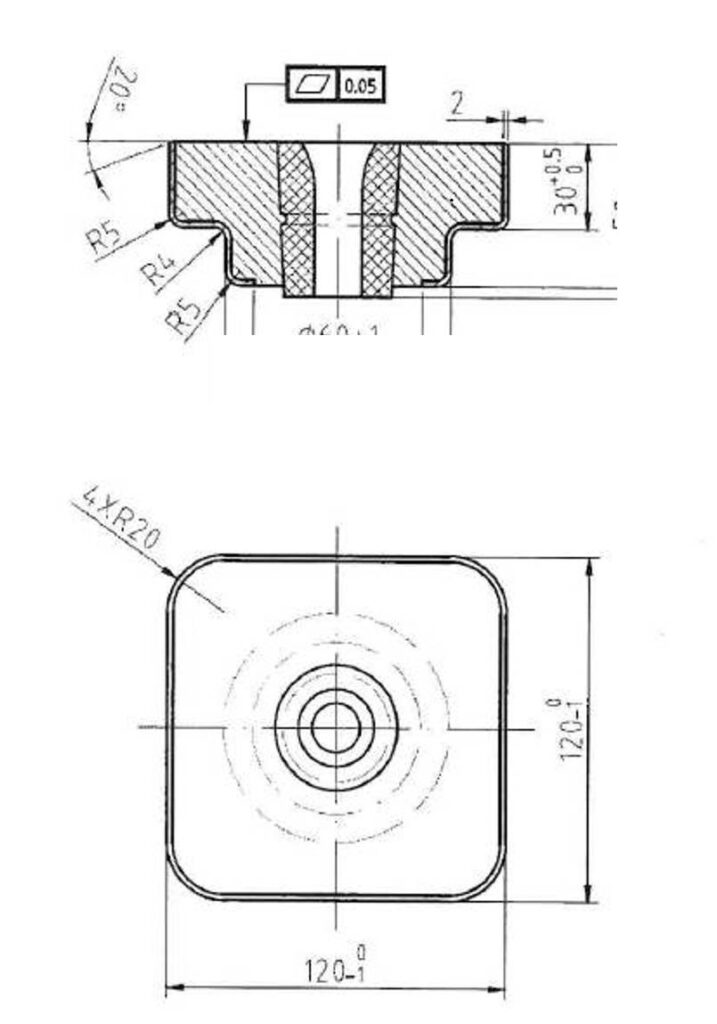

The nozzle in use and the spare nozzle are placed on the same plane, supported by high-temperature resistant springs, and the nozzle is replaced by hydraulic ejection; The quick replacement of the sizing nozzle adopts a specific mechanical device, which has a metering nozzle running slide with precise dimensions. The metering nozzle in working condition and the spare metering nozzle are both positioned in the slide. When it is necessary to replace the metering nozzle, press the start button, and the hydraulic drive device will push the spare nozzle from the spare position to the working position within 0.1s. The original working nozzle will be pushed to the collection position. The molten steel will be injected into the crystallizer through the new nozzle, thereby realizing the rapid replacement of the metering nozzle during continuous casting. After replacement, the center line deviation of the upper and lower nozzles is less than 0.1mm.

2.Manual rapid change method:

The nozzle in use and the spare nozzle are placed in the same plane in a fan shape, mechanically fixed, and manually operated for replacement. The manual replacement mechanism is simple and consists of four parts: base, fixed plate, fan plate, and spring pressure regulator. The fan-shaped slide frame contains two sizing nozzles. By moving the handle of the fan-shaped frame, the casting hole of one nozzle on the fan-shaped slide frame can be put into working state, while the other nozzle has been moved to the other side of the device. At this time, the removed nozzle brick can be replaced. The characteristics of this device are:

(1) The device has a reasonable structure, simple construction, convenient maintenance, and low labor intensity.

(2) A unique spring pressure regulator is used to apply a certain pre-pressure to the nozzle, which can quickly replace the nozzle brick without interrupting the flow. In the 1990s, Laiwu Steel took the lead in overcoming the problem of rapid replacement of sizing nozzles in my country, realizing the rapid replacement of sizing nozzles in continuous casting tundishes and the technology of tundish long service life, thus launching a wave of application of sizing nozzle rapid replacement systems in China.

3.The advantages of the rapid change mechanism for metering nozzles include:

1. Applying the rapid replacement technology for metering nozzles can avoid excessive casting speed and steel leakage accidents caused by excessive nozzle erosion.

2. It can increase the number of continuous castings per ladle, reduce the residual steel in the tundish, improve the billet yield and billet quality, and achieve the goal of reducing costs and increasing benefits.

3. It can realize rapid stopping and restarting of casting and replacement of sizing nozzles of different diameters during casting, so as to adapt to the best matching of steel temperature, fluidity and casting speed in the later stage of casting and the matching with the steel supply in front of the furnace, and promote the balanced and stable production organization.

4. It can improve the service life of the tundish and reduce the consumption of refractory lining materials, ladle drying energy, ladle construction manpower, etc. However, the quick-change system cannot be used continuously without limit. Although the drain outlet can be replaced, the inlet outlet cannot. After a long period of use, the inlet outlet will also become unusable due to excessive expansion. In addition, after a long period of use, the high-temperature spring will also cause the drain outlet to fail to maintain a good horizontal contact with the inlet outlet due to inconsistent elasticity, resulting in steel leakage.