As a key functional refractory material used in the continuous casting of small square billets, the metering nozzle plays a crucial role in controlling the flow rate of molten steel, determining the billet casting speed, and is essential for ensuring the normal operation of continuous casting. It is thus known as a functional refractory material for continuous casting. Besides preventing cracking, blockage, and detachment during initial pouring, the metering nozzle must also have a controlled expansion rate to meet the requirements of long-term casting.

To achieve cost savings, the ideal service condition for the three types of tundish refractories with different functions is synchronous failure. However, with the application of fourth-generation dry vibrating lining/coated working liners in tundishes, their service life has significantly increased, exceeding 60 hours. In contrast, the service life of the metering nozzle has not kept pace, which is currently a bottleneck restricting the overall improvement of the service life of continuous casting tundishes.

Currently, the production process of sizing nozzles for tundishes used in continuous casting of small billets in China is generally as follows: using PSZ particles as 10 aggregate, adding magnesium oxide or calcium oxide as stabilizers to monoclinic zirconia fine powder as the matrix, and then adding a small amount of binder and additives, after mixing and granulation, it is dry-pressed and the firing temperature is generally between 1650℃ and 1760℃. Its production process flow is shown in Figure 1.

The production process of sizing nozzles plays a crucial role in their performance. Process parameters such as the particle size distribution of raw materials, mixing time, molding pressure, drying method, and firing regime all affect the various properties of the nozzle. By controlling the production process factors such as granulation, molding, and firing, the service life of sizing nozzles can be improved.

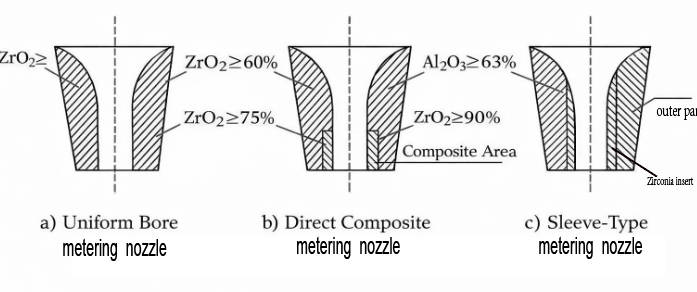

According to their structure, sizing nozzles can be divided into three categories: homogeneous sizing nozzles, direct composite sizing nozzles, and embedded sizing nozzles, as shown in Figure 2.

(1) Homogeneous metering nozzles. It is mainly made of zircon or zircon with zirconium oxide added in a certain proportion, and then formed, dried and sintered (firing temperature is 1620-1650℃). It contains 60-90% ZrO2. Its characteristics are good integrity, relatively uniform composition, performance and structure, high strength, corrosion resistance, and good usability, but the cost is high and the lifespan is relatively short.

(2) Direct composite metering nozzle. To reduce production costs, ordinary zircon metering nozzles can be made into a direct composite type. In this type of metering nozzle, the inner and outer layers use different raw materials during forming. The nozzle body is made of zircon material, and the inner hole part (working surface) of the sizing end is made of a composite of zircon and zirconium oxide. The zirconium oxide content of the composite part is 72%-78%. The body and the composite part are formed simultaneously and fired once at a firing temperature of 1620-1650℃. The cost of this type of nozzle is much lower than that of a fully homogeneous sizing nozzle. Since the main body and composite part of the sprue are formed and fired simultaneously, the composite part will not fall off during use. However, because zirconium oxide undergoes a phase transformation and volume change at 1100-1250℃, the sprue is prone to cracking during use. Therefore, stabilized zirconium oxide must be used in the production of this type of sprue, and its content should not be too high. Since the thermal expansion coefficients of stabilized zirconium oxide and zircon are still inconsistent, the sprue may also crack during use. Its advantages are good integrity of the sprue, no bonding seam, high strength, high corrosion resistance, safe and reliable use, and low price; its disadvantage is that it is difficult to manufacture and needs to solve the problem of inconsistent thermal expansion coefficients of the two raw materials.

(3) Sleeve typed metering nozzle. This type of tundish metering nozzle is divided into two parts during production: the seat brick and the zirconia insert, which are then joined together with fire mortar. The seat brick is made of high alumina material and only serves to fix and support the inner insert; its functional requirements are not high. The inner zirconia insert plays a crucial role in flow control and is generally made of zirconium oxide. The specific composition and production process can be adjusted according to different usage requirements. Currently, its production mainly uses raw materials with high zirconium oxide content (ZrO2>90%), which are then formed and fired at high temperatures to achieve long service life. Embedded metering nozzles solve the cracking problem caused by the thermal expansion mismatch between the inner and outer layers of composite nozzles. They have better thermal stability than direct composite metering nozzles and are less expensive. Their service life can be adjusted according to the ZrO2 content of the inner zirconia insert, and they are currently widely used.

Based on the particle size of the raw materials used in the production of tundish metering nozzles, they can be divided into three types: coarse-grained, fine-grained, and ceramic-type tundish metering nozzles.

(1) Coarse-grained zirconium oxide metering nozzles: These nozzles have relatively coarse particles (up to 2mm), resulting in less shrinkage after firing, good thermal shock stability, and rarely cracking during use. However, these nozzles have low pressure resistance and high apparent porosity, leading to poor resistance to erosion and scouring, and a short service life.

(2) Fine-grained zirconia metering nozzles: These nozzles use raw materials with a particle size <50 μm, resulting in products with a uniform microstructure, low apparent porosity, high compressive strength, and good resistance to erosion and corrosion. However, compared to coarse-grained nozzles, they may crack during the initial casting process, leading to abnormal casting stoppages.

(3) Ceramic-type zirconia tundish metering nozzles: These nozzles use raw materials with a particle size <5 μm, resulting in products with exceptionally low apparent porosity, high compressive strength, and long service life. This reduces the need for frequent tundish replacements during continuous casting, minimizing downtime (preparation) and losses, and improving casting machine efficiency. However, ceramic-type products have poor thermal shock resistance; improper use can cause nozzle cracking. Therefore, measures must be taken to reduce the thermal stress experienced by the nozzle during initial casting when producing and using ceramic-type zirconia sizing nozzles. Damage to Zirconia Sizing Nozzles

Damage to the metering nozzle

The damage process of zirconia metering nozzles is a complex physicochemical interaction between them and steel slag and molten steel at high temperatures. The specific damage mechanisms are divided into two main categories:

(1) Physical Damage: Thermomechanical scouring damage. During use, the large temperature difference before and after steel casting (casting temperature 1540℃) causes uneven heating, generating significant thermal stress inside the nozzle, leading to micro-cracks. These cracks reduce the nozzle’s strength and scouring resistance, facilitating the penetration and erosion of molten steel and slag into the nozzle.

(2) Chemical Damage: ① Desolvation of stabilizers in zirconia. Currently, the best raw material for preparing sizing nozzles is partially stabilized zirconia. During steel casting, stabilizers (calcium oxide, …) are dissolved in the zirconia solution. Magnesium oxide (MgO, etc.) reacts with molten steel and inclusions in the steel (such as Fe, Mn, Si, etc.) to form low-melting-point oxide melts, which are carried away with the molten steel. Furthermore, the zirconia solid solution decomposes due to the desolvation of the stabilizer, resulting in a reduction in the amount of cubic zirconia, which transforms into small monoclinic particles that are lost with the molten steel. ② Penetration and erosion by molten steel and slag. Due to the desolvation of the stabilizer, certain conditions are provided for the penetration and wetting of zirconia particles by molten steel and slag, causing some coarse particles to detach. Simultaneously, this… The process causes tetragonal zirconia to transform into monoclinic zirconia, ultimately leading to the separation of fine-grained zirconia from the hot face.

Current Status and Problems of Metering Nozzles

Due to the high cost of zirconia raw materials and product firing, embedded zirconia tundish metering nozzles are currently the primary method used in actual production to reduce costs. This involves using lower-cost high-alumina or zircon materials for the nozzle outer casing, while the nozzle core (working face) is made of zirconia using fire-clay inlay, enabling continuous casting across multiple furnaces.

With the increasing service life of tundish linings, tundish metering nozzles have become a bottleneck restricting the overall lifespan of continuous casting tundishes. To address this, a quick-change mechanism for tundish metering nozzles has been developed domestically and is already in production. This device can replace unusable nozzles within 0.1 seconds while ensuring uninterrupted flow, extending casting time. Currently, most steel mills in China have adopted this device, increasing continuous casting time to over 20 hours, with some reaching over 40 hours.

From a practical application perspective, the quick-change mechanism cannot indefinitely extend the lifespan of the nozzle. The purpose of use is to improve the lifespan of zirconia metering nozzles. While the lower nozzle can be replaced at any time, the upper nozzle cannot be replaced during the casting process. After prolonged use, the upper nozzle will be damaged due to excessive diameter expansion and other reasons, rendering it unusable. Therefore, when using a quick-change mechanism for metering nozzles, the key is to improve the service life of the nozzle itself. Foreign researchers, without reducing the thermal shock stability of the nozzle, have increased its service life by 1.4 to 1.5 times by densifying the working surface (flowing steel surface) of the nozzle through surface modification.

Tang Xunhai et al. used industrial inorganic salt Zr℃h.8H2O as a precursor and CO(NH2)2 as a hydrolysis accelerator to modify the surface of zirconia metering nozzles using a sol-gel process. The results showed that the pore area and pore volume of the sample were significantly reduced after surface treatment. Moreover, without reducing the thermal shock resistance, the corrosion resistance and erosion resistance of the metering nozzle were significantly improved, and the service life was increased by more than 1.4 times.

Gu Zhihua et al. combined the sol-gel method to… The surface coating process for engineering ceramics utilizes zirconia sol to treat the surface of the metering nozzle blank, densifying the nozzle surface, significantly reducing its porosity, and making the nozzle structure more compact, thus effectively preventing nozzle diameter expansion and laying the foundation for improving continuous casting time.

Gao Licun et al. used powder molding technology, rationally controlling particle size distribution and optimizing process parameters, to obtain zirconia sizing nozzles with low apparent porosity, high bulk density, and high thermal shock resistance.

Li Xiang, Zhang Hui, and Zhao Liang prepared modified sizing nozzles by adding MgO-Al2O3-ZrO2 composite powder to the zirconia raw material. The magnesium aluminum spinel formed by Al2O3 and the stabilizer MgO fills the pores due to volume expansion and prevents abnormal growth of zirconia particles during firing, thus improving the density and strength of the sizing nozzle. The MgO in the composite powder reduces the consumption of MgO stabilizer in the raw material by the magnesium aluminum spinel, reducing stabilizer desolvation, thereby ensuring the stability of the metering nozzle and improving its service life.